Working principle of Flame Arresters

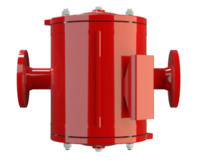

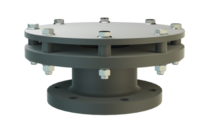

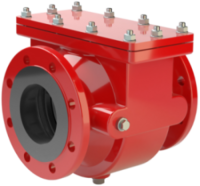

A Flame Arrester is designed to allow the safe flow of gases and liquids while preventing flame transmission.

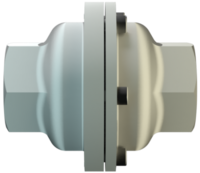

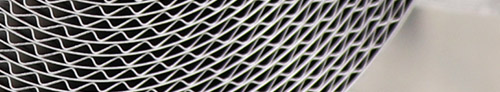

Flame Arresters are composed of spirally wound metal bands with precisely reproducible flame-quenching gaps. These gaps are adjusted to the ignition transmission capability of explosive vapors.

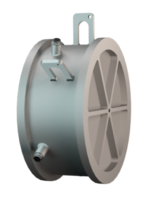

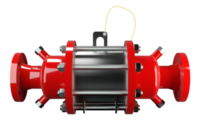

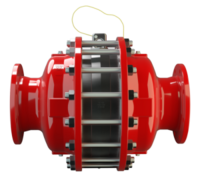

The FLAMEFILTER® is made of wound metal strips and forms an effective band arrester. This flame-quenching principle is applied in PROTEGO® end-of-line flame arresters and in-line flame arresters.

When a mixture ignites in a gap, the flame spreads towards the unburned mixture. The volume expansion of the burned mixture pre-compresses the unburned mixture and accelerates the flame propagation. Heat dissipation to the large surface of the gap lowers the temperature below the ignition temperature, thus extinguishing the flame.

The gap width and gap length determine the extinguishing effectiveness of the Flame Arrester. A narrower and longer gap extinguishes the flame more effectively, while a wider and shorter gap reduces the pressure loss. Experiments can determine the optimum solution between the two conditions.

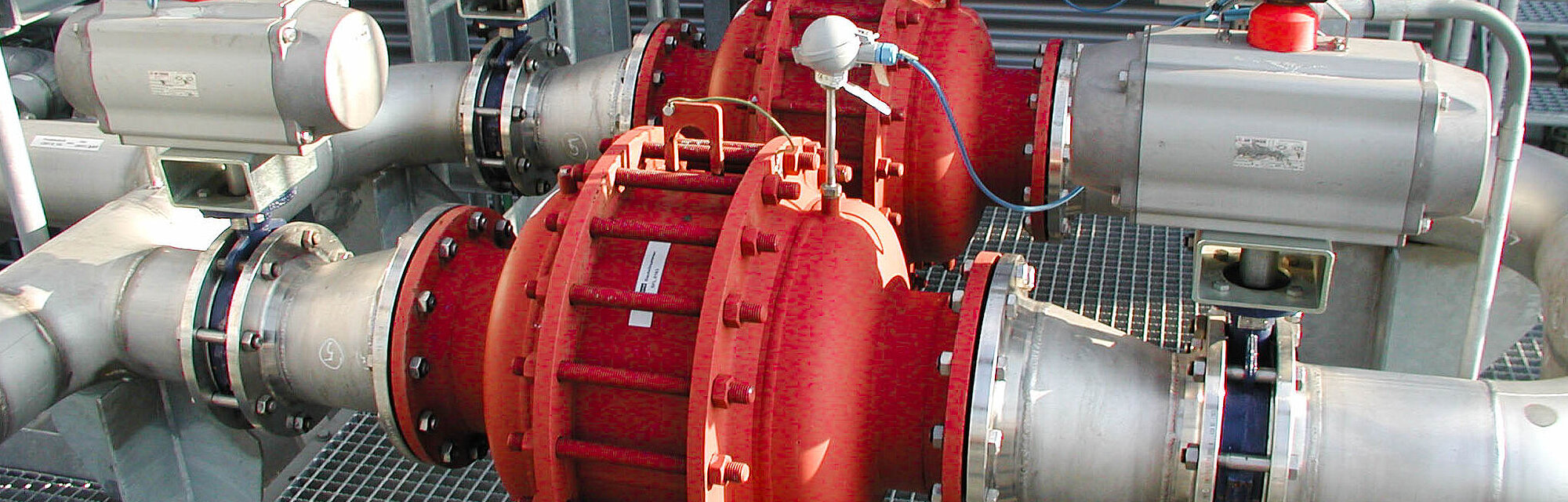

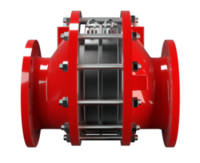

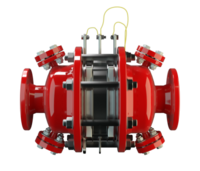

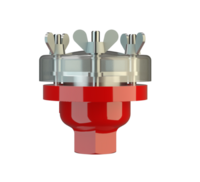

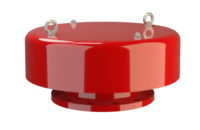

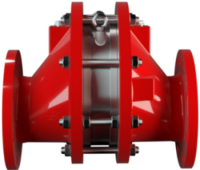

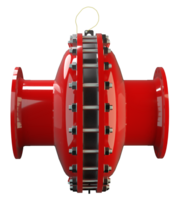

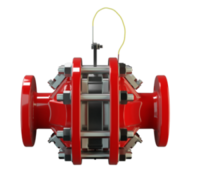

PROTEGO® Flame Arresters in a highly maintenance-friendly design

This design prevents the FLAMEFILTER® discs from being damaged or misaligned during assembly or maintenance.

These PROTEGO® Flame Arresters are particularly suited to applications where more frequent maintenance of the FLAMEFILTER® is required (e.g., where polymerization or crystallization result in heavy contamination) or for IIC applications.

After installation, PROTEGO® units can be retrofitted at any time.

For detailed information, please select a product from our range below.

Explosion Group:

IIA1,

D / IIA,

C / IIB1,

C / IIB2,

C / IIB3

Explosion Group:

IIA1,

D / IIA,

C / IIB1,

C / IIB2,

C / IIB3

Explosion Group:

IIA1,

D / IIA,

C / IIB1,

C / IIB2,

C / IIB3

Explosion Group:

IIA1,

D / IIA,

C / IIB1,

C / IIB2,

C / IIB3

Explosion Group:

IIA1,

D / IIA,

C / IIB1,

C / IIB2,

C / IIB3

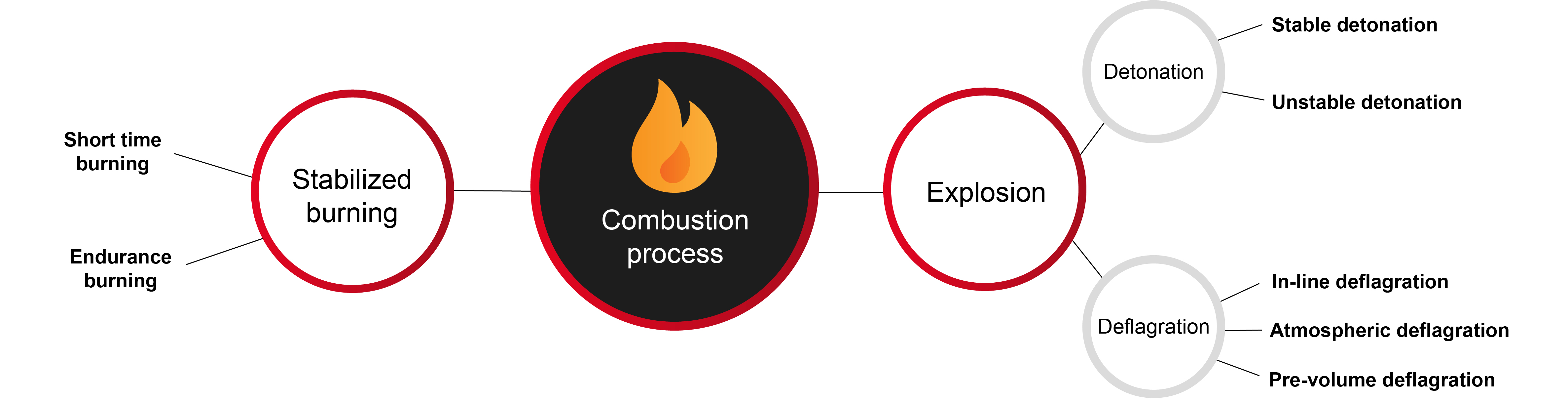

The video explains the differences and characteristics of deflagration and detonation.

Different gases have different flame propagation capacities and are categorized into explosion groups corresponding to their hazard level. The standard for this is the MESG = Maximum Experimental Safe Gap, a characteristic number measured in the laboratory for the flame propagation ability of the product.

The MESG, or standard gap width, is the largest gap width between the two parts of the interior chamber of a test setup which, when the internal gas mixture is ignited and under specified conditions, prevents ignition of the external gas mixture through a 25 mm long gap, for all concentrations of the tested gas or vapor in air.

The MESG is a property of the respective gas mixture [EN 1127-1]. NOTE: The test setup and methods are specified in EN 60079-20-1. The most explosive composition is close to the stoichiometric mixture of the gas/vapor-air mixture.

| Explosion group | Max. Experimental Safe Gap (mm) | NEC | Reference Substances for testing flame arrester |

|---|---|---|---|

| IIA1* | ≥ 1,14 | Methane | |

| IIA | > 0,90 | D | Propane |

| IIB1 | ≥ 0,85 | C | Ethylene |

| IIB2 | ≥ 0,75 | C | Ethylene |

| IIB3 | ≥ 0,65 | C | Ethylene |

| IIB | ≥ 0,5 | B | Hydrogen |

| IIC | < 0,5 | B | Hydrogen |

The table shows the categorization of substances into the respective explosion group according to their MESG (IEC 79-1, EN ISO 16852).

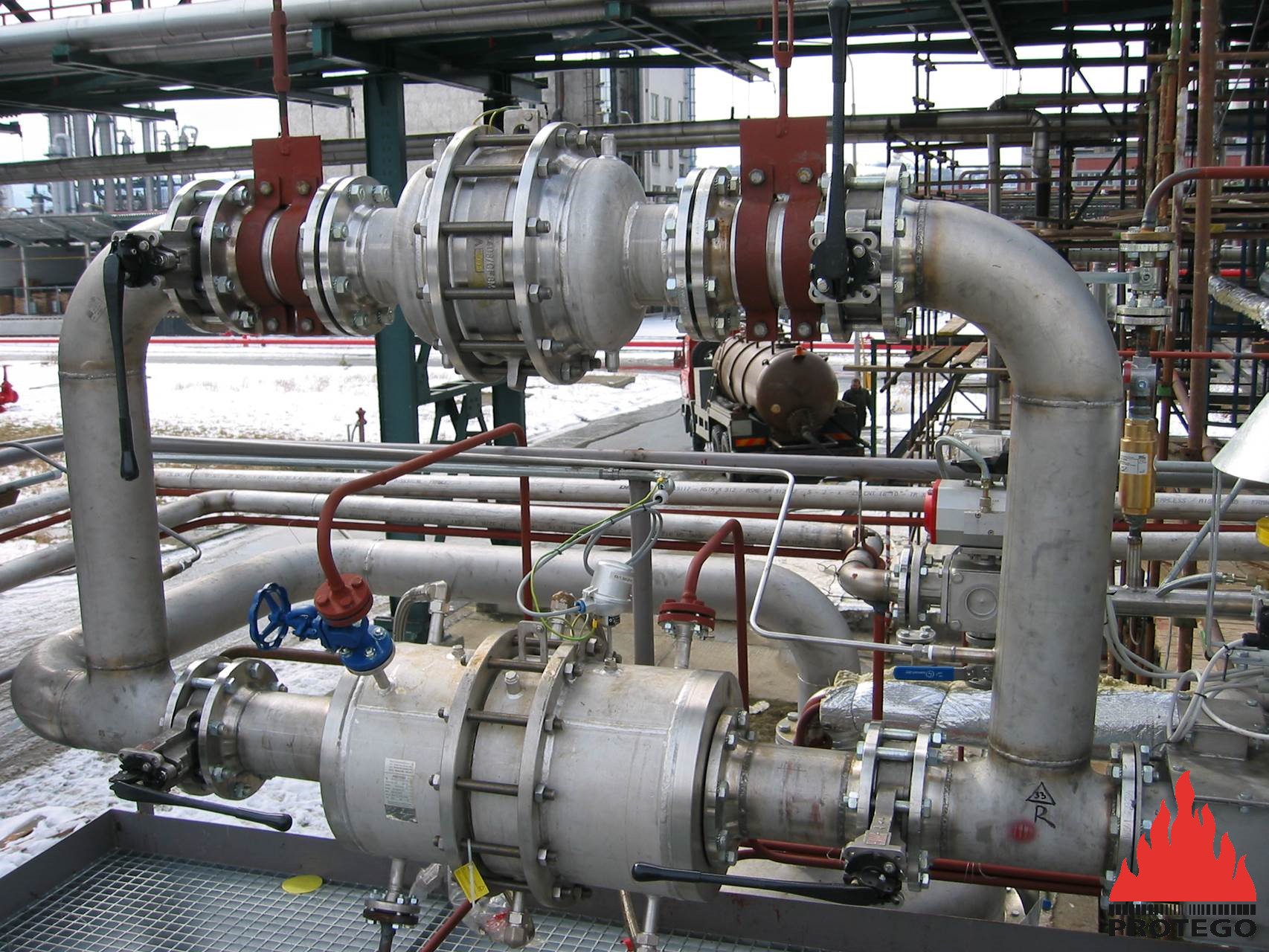

Special Flame Arrester Solutions

DMT Applications

Superheated Valves and Flame Arrester

Acetylene Applications

PROTEGO® DA-SB-AC Detonation Flame Arrester

Ethylene Oxide Applications

PROTEGO® DA-SB-EO - Detonation Flame Arrester