Working together for Safety and Environment

As the headquarters of the PROTEGO® Group, Braunschweiger Flammenfilter GmbH is responsible for 12 locations and over 650 employees worldwide. As the global market and technology leader in the field of flame arresters, valves and tank equipment for the up and downstream oil and gas, petroleum, chemical, pharmaceutical and bio-energy industries, we not only place the highest demands on ourselves, but also on our suppliers and business partners.

Our purchasing portfolio includes the following product groups:

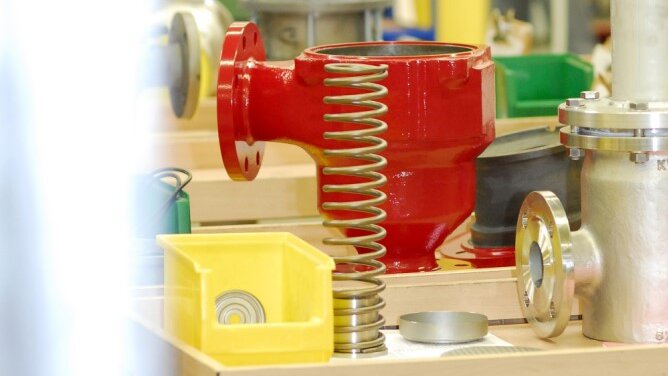

To ensure the functionality of our products, we procure various formed parts. These include springs, rings as well as construction items such as deep-drawn parts and formed/welded constructions. The specifications of the individual parts are based on the respective requirements of our end product and are determined individually.

We have the following requirements for our suppliers:

- ISO 9001

- ISO 14001 (preferred)

- Additional specific requirements/certifications depending on the manufacturing process

Sustainability and social responsibility along the supply chain

As a globally active company, we are also aware of our social responsibility and actively take measures to fulfill this responsibility towards people and the environment.

Supplier Code of Conduct

Our actions are guided by our Supplier Code of Conduct. We also expect our business partners to uphold the worldwide preservation of human rights and responsible use of available resources. We require our suppliers recognize our Supplier Code of Conduct or acknowledge the mutual commitment to their own code if it is comparable to ours.

More information on the CoC for suppliers

Conflict Minerals Policy

We occasionally purchase products made from tantalum. These have been subject to Regulation (EU) No. 2017/821 Conflict Minerals since 01.01.2021. We fully support this regulation as part of our voluntary due diligence and request a fully completed Conflict Minerals Reporting Template (CMRT) from all affected suppliers without exception.

Regulation on Conflict Minerals

Supply Chain Due Diligence Act

Even though the PROTEGO® Group is not currently subject to the extensive regulations of the Supply Chain Due Diligence Act, we consider it our societal obligation to secure our global supply chain by recognizing risks early and taking appropriate measures. Our risk management is diverse and includes supplier visits, audits, and special CSR audits with our global suppliers.

PROTEGO® Information Letter on the Supply Chain Due Diligence Act

Get in touch

We ask for your understanding that inquiries can only be processed via the contact form below.