Protection of Processing Facilities

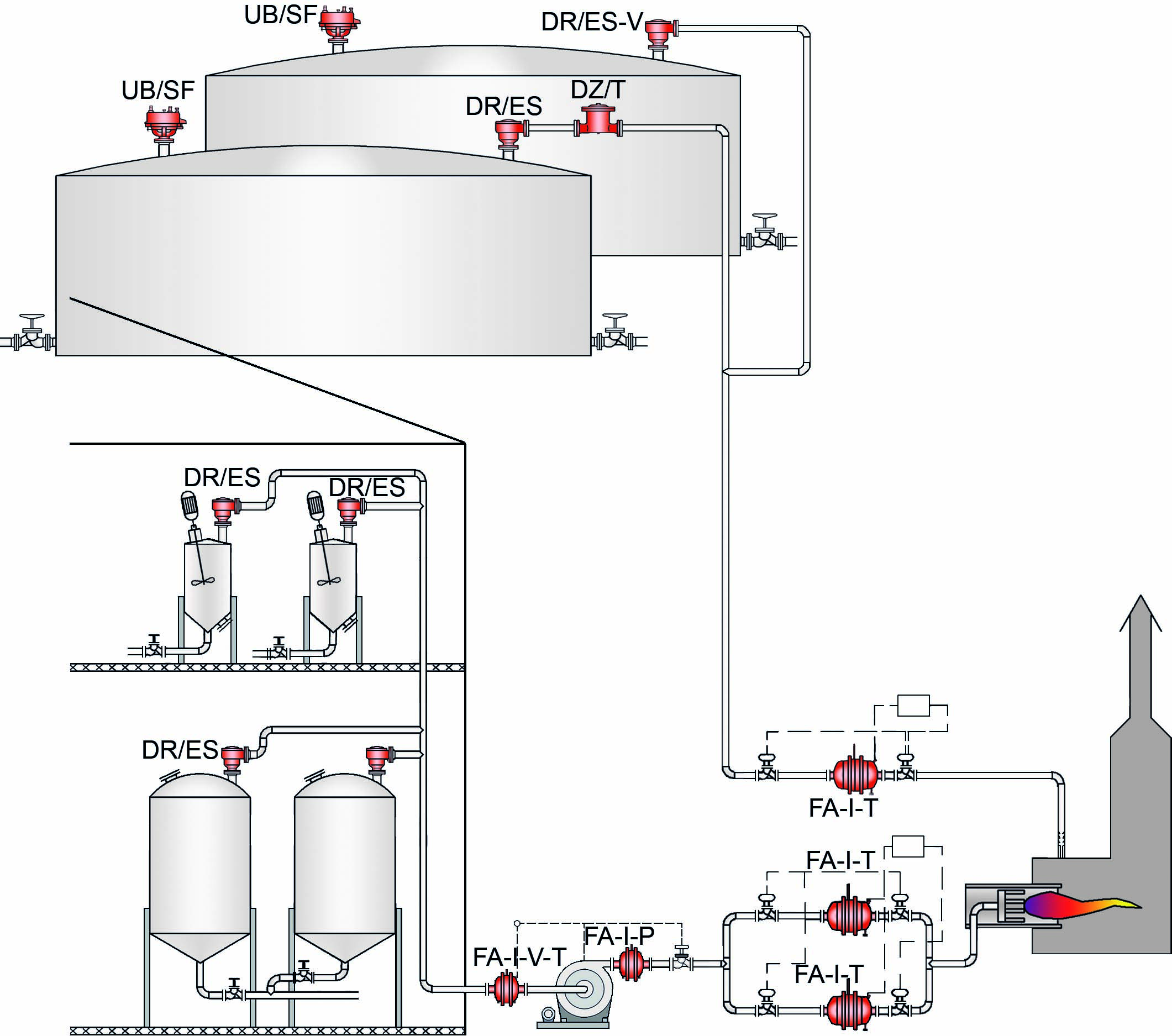

- Tank farms for flammable liquids with pressure and vacuum relief diaphragm valve UB/SF, connection to gas vent header system with detonation flame arrester DR/ES-V or DR/ES and pressure or vacuum relief valve DZ/T.

- Ventilation of industrial mixers and process vessels in a common vapour vent header via detonation flame arresters DR/ES.

- Temperature-monitored deflagration flame arresters FA-I-T in the feed line for vapour combustion at the maximum allowable distance from the ignition source and in parallel for the sake of availability for servicing or emergency switching in case of an endurance burning on the arrester. Vapour pipeline from plant to vapour combustion unit with deflagration flame arrester FA-I-T to protect the vent header collection line and the operating locations in the plant.

- Protecting pressure-resistant radial blowers as type-examined zone-0 blowers with integrated PROTEGO® flame arresters FA-I-V-T and FA-I-P.

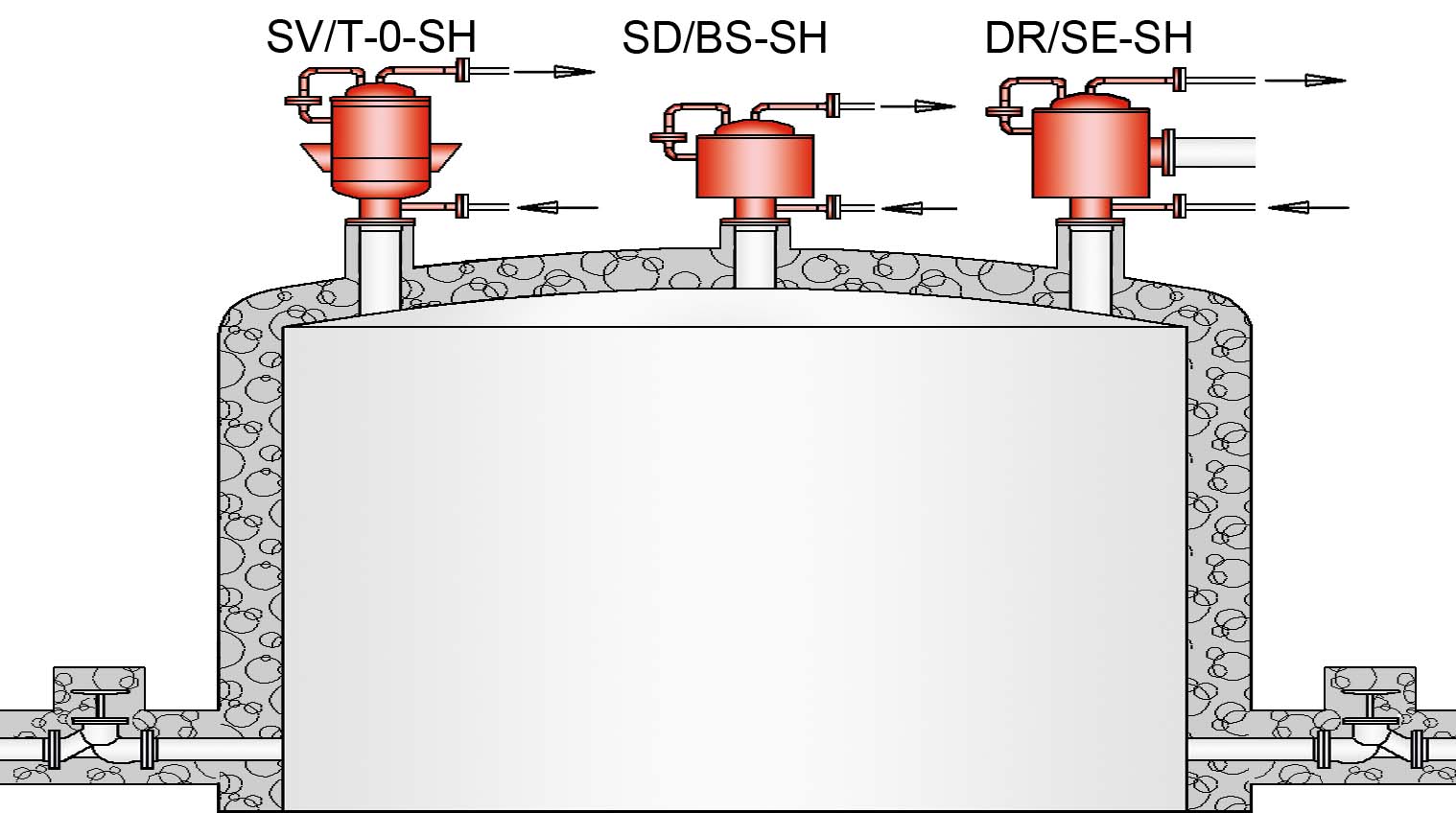

Protection of storage tanks for bitumen

Protection of storage tanks for media that can only be pumped with assistance of heating systems. These applications, e.g. bitumen storage, need fully heated devices such as the pressure relief valve SD/BS-H, vacuum relief valve SV/T-0-H and heated detonation flame arrester DR/SE-SH to a heating temperature of the heating jacket to 320°C at 6 bar.

What about your application?

Contact our specialists for your individual requirements.