FA-CN-IIC

In-Line Deflagration Flame Arrester for hydrogen/air-mixtures, concentric design, bidirectional

- state of the art protection for any hydrogen/air mixture

- can be applied to process flows with small liquid or particle load

- compact design with easy access cover

- easy maintenance without disassembling of the pipeline

- modular flame arrester unit enables individual FLAMEFILTER® to be replaced and cleaned

- bi-directional flame transmission proof design

- protects against deflagrations for all explosion groups

- lowest pressure drop results in low operating and lifecycle costs

- modular design reduces spare parts cost

Function and Description

The PROTEGO® FA-CN in-line deflagration flame arrester is a compact design utilizing an easy access cover for easy maintenance. The special PROTEGO® FA-CN-IIC version was developed for hydrogen applications (group IIC vapors – NEC group B). The device is designed with relatively large gap widths – related to IIC – which causes minimum pressure loss and allows for permeation of small liquid droplets or particles. The PROTEGO® flame arrester unit can be removed and cleaned in just a few simple steps having to disassemble the pipe. When installing the deflagration flame arrester, make sure that the distance between potential ignition sources and thelocation of the installed device does not exceed the L/D ratio (pipe length/ pipe diameter) for which the device was approved (see table 4).

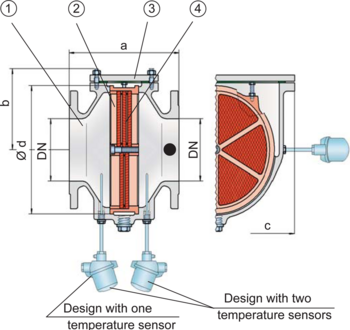

The deflagration flame arrester is symmetrical and offers bidirectional flame transmission protection. The device consists of the housing (1) with an easy access cover (3) and the PROTEGO® flame arrester unit (2) in the center. The PROTEGO® flame arrester unit is modular and consists of several FLAMEFILTER® discs (3) and spacers firmly held in a FLAMEFILTER® casing. The number of FLAMEFILTER® discs and their gap size depend on the device’s intended use.

Specifying the operating conditions, such as the temperature, pressure, explosion group, and the composition of the fluid, enables PROTEGO® to select the best deflagration flame arrester for your application. The versions of PROTEGO® FA-CN-IICflame arrester protect against deflagrations of fuel/air mixtures of explosion group IIC (NEC B). FA-CN devices for substances of explosion groups IIA1, IIA, and IIB3 (NEC D and C (MESG ≥ 0.65 mm) are shown on separate pages.

The standard design can be used with an operating temperature of up to +60°C / 140°F and an absolute operating pressure up to 1.1 bar / 15.9 psi.

Type-approved in accordance with the current ATEX Directive and EN ISO 16852, as well as other international standards.

Dimensions

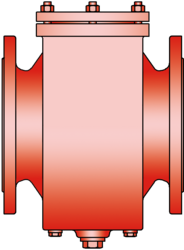

To select the nominal size (DN), use the flow capacity charts on the following pages

| DN | 40 / 1½“ | 50 / 2“ | 65 / 2½“ | 80 / 3“ | 100 / 4“ | 125 / 5“ | 150 / 6“ | 200 / 8" | 250 / 10" | 300 / 12" |

| a | 210 / 8.27 | 215 / 8.46 | 235 / 9.25 | 240 / 9.45 | 265 / 10.43 | 305 / 12.01 | 310 / 12.20 | 300 / 11.81 | 320 / 12.60 | 350 / 13.78 |

| b | 105 / 4.13 | 105 / 4.13 | 132 / 5.2 | 132 / 5.2 | 150 / 5.91 | 197 / 7.75 | 197 / 7.75 | 220 / 8.66 | 260 / 10.24 | 295 / 11.61 |

| c | 200 / 7.87 | 200 / 7.87 | 260 / 10.24 | 260 / 10.24 | 308 / 12.13 | 415 / 16.34 | 415 / 16.34 | 446 / 17.56 | 520 / 20.47 | 600 / 23.62 |

| d | 130 / 5.12 | 130 / 5.12 | 185 / 7.28 | 185 / 7.28 | 220 / 8.66 | 310 / 12.20 | 310 / 12.20 | 355 / 13.98 | 420 / 16.54 | 490 / 19.29 |

Material selection

| Design | A | B |

| Housing | Steel | Stainless Steel |

| Cover | Steel | Stainless Steel |

| Gasket | PTFE | PTFE |

| Flame arrester unit | Stainless Steel | Stainless Steel |

Selection of explosion group

| MESG | Expl. Gr. (IEC / CEN) | Gas Group (NEC) |

| < 0,50 mm | IIC | B |

Selection of max. operating pressure

| DN | 40 / 1½" | 50 / 2" | 65 / 2½" | 80 / 3" | 100 / 4" | 125 / 5" | 150 / 6" | 200 / 8'' | 250 / 10'' | 300 / 12'' |

| Pmax | 1,1 / 15.9 | 1,1 / 15.9 | 1,1 / 15.9 | 1,1 / 15.9 | 1,1 / 15.9 | 1,1 / 15.9 | 1,1 / 15.9 | 1,1 / 15.9 | 1,1 / 15.9 | 1,1 / 15.9 |

Max. allowable L/D-ratio

| DN | 40 / 1½" | 50 / 2" | 65 / 2½" | 80 / 3" | 100 / 4" | 125 / 5" | 150 / 6" | 200 / 8'' | 250 / 10'' | 300 / 12'' |

| (L / D)max | 30 | 30 | 10 | 10 | 10 | 20 | 20 | 10 | 10 | 5 |

| Designation | - | - | X12 | X12 | X12 | X10 | X10 | X12 | X12 | X13 |

Flange connection type

| EN 1092-1; Form B1 |

| ASME B16.5 CL 150 R.F. |

Design Types and Specifications

There are three different designs:

Basic in-line deflagration flame arrester | FA-CN - – |

In-line deflagration flame arrester with integrated temperature sensor* as additional protection against short-time burning from one side | FA-CN - T |

In-line deflagration flame arrester with two integrated temperature sensors* for additional protection against short-time burning from both sides | FA-CN - TB |

Additional special devices available upon request

*Resistance thermometer for device group II, category (1) 2 (GII cat. (1) 2)

Flow Capacity Chart

The flow capacity charts have been determined with a calibrated and TÜV certified flow capacity test rig. Volume flow V in (m³/h) and CFH refer to the standard reference conditions of air ISO 6358 (20°C, 1bar). For conversion to other densities and temperatures refer to Sec. 1: “Technical Fundamentals”.