We find the perfect solution for you

We support our customers by developing and optimizing devices for protection against overpressure and vacuum, deflagrations, detonations and burning. Whatever complex and extreme your application, we will find a solution for you. We are specialists, not only specializing in what we have already developed, but also in developing the dedicated solutions you may require. Tailored devices are our day-to-day business.

The PROTEGO® technology center is equipped with the following test facilities: low pressure measurement systems, climate chamber, cryogenic test bench, salt spray chamber, valve test bench, mechanical workshop, laboratory and electrical laboratory.

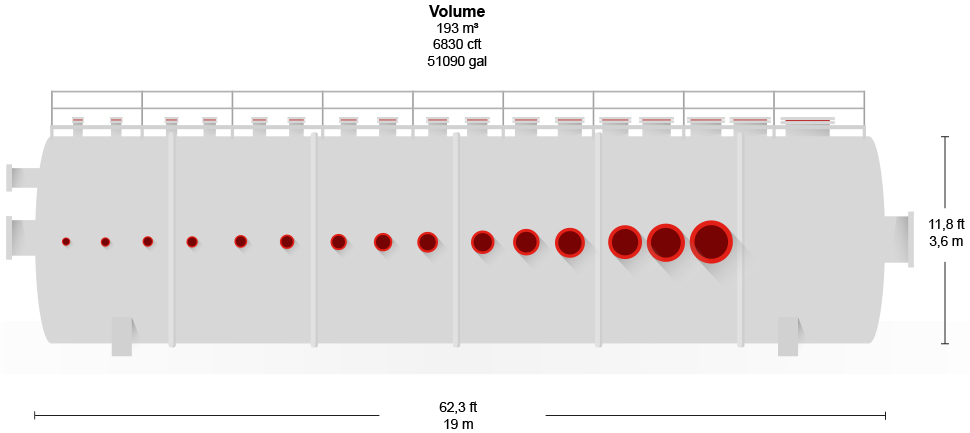

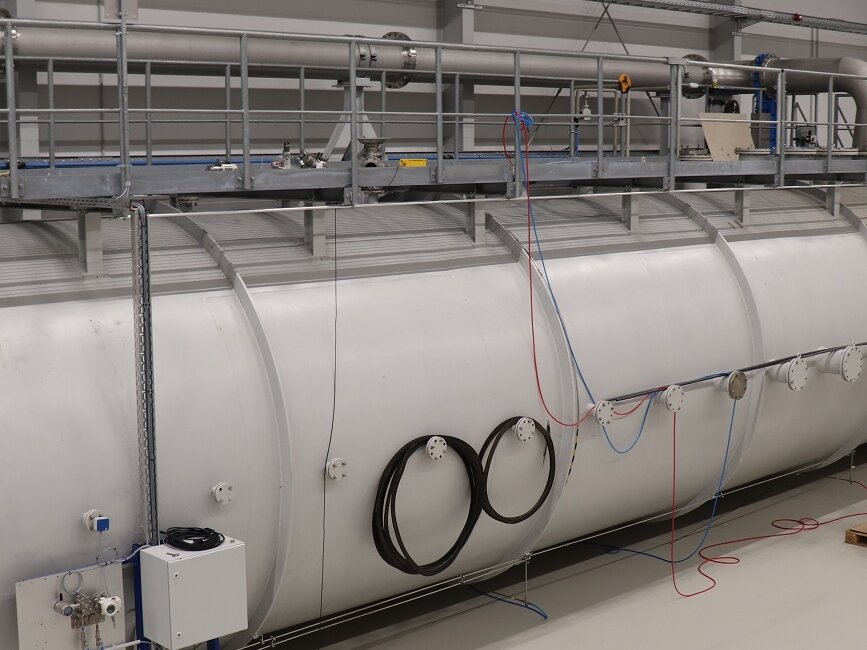

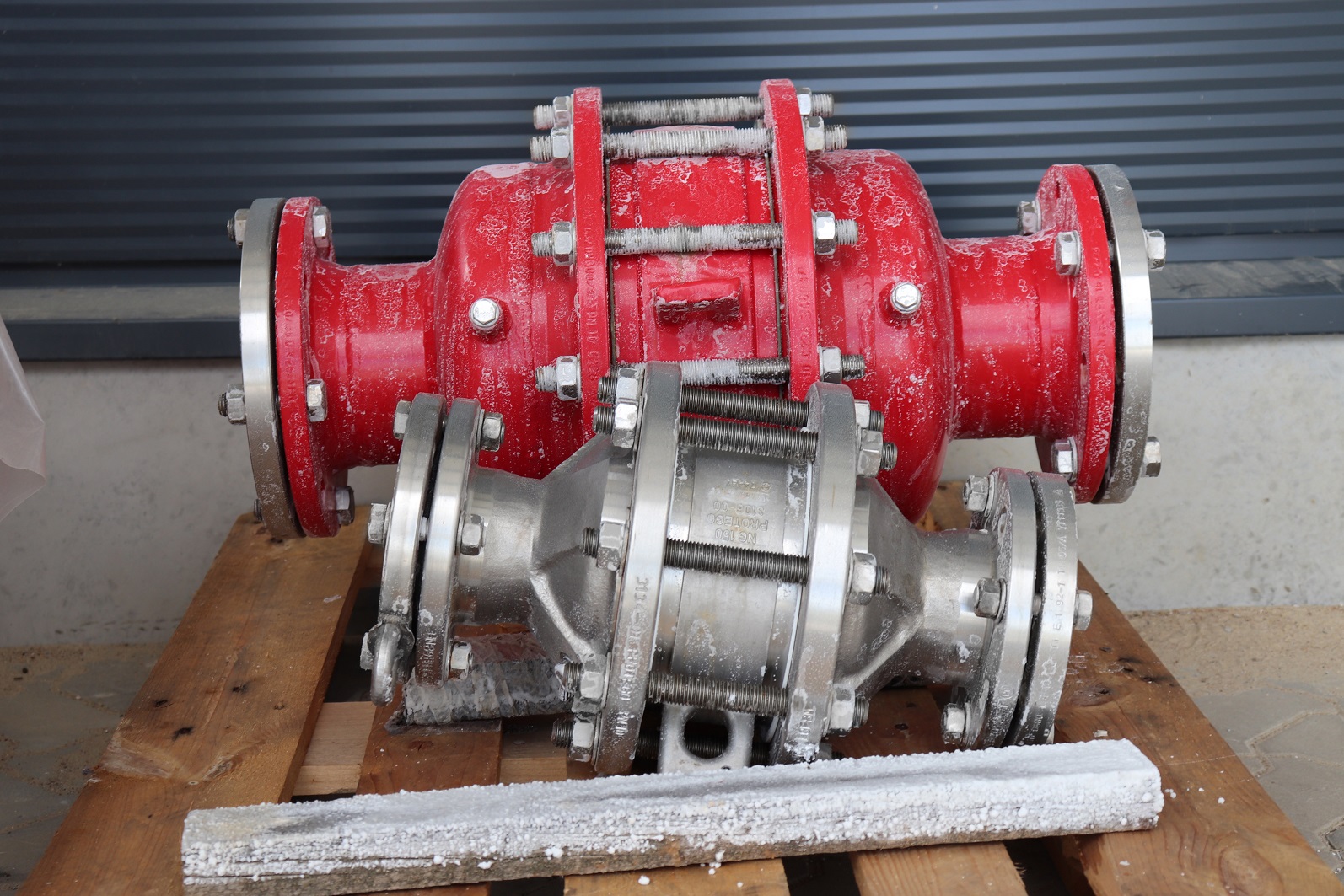

The world's largest flow test facility of its kind

Our products stand for quality and safety. The world's largest flow test facility of its kind, it is also an indispensable tool for internal research and development to enable correct scientific measurement of flow and meet specific customer requirements. All PROTEGO® valves and flame arresters are flow tested to assure safe operation in service.