PROTEGO® Safety Solutions for the Maritime Industry

PROTEGO® offers advanced explosion protection and safety solutions for Shipbuilding, Offshore Platforms and Loading systems. With our specialized PROTEGO® Flame Arresters and Breather Valves, we ensure compliance with international standards, such as IMO MSC.1/Circ.1621, EN ISO 16852, ISO/IEC 80079-49 and ISO 15364. These solutions safeguard sustainable fuel applications, protecting vessels and offshore systems from atmospheric deflagration, detonation and endurance burning.

From inland waterway tankers to FPSOs, our technology addresses the unique safety challenges of marine and offshore industries, including compliance with ADN and API 2000 standards.

Our robust safety concepts feature innovative designs tailored for specific requirements, ensuring optimal performance and safety in high-risk environments.

Discover our comprehensive solutions and applications below and explore how PROTEGO® can enhance safety in your operations

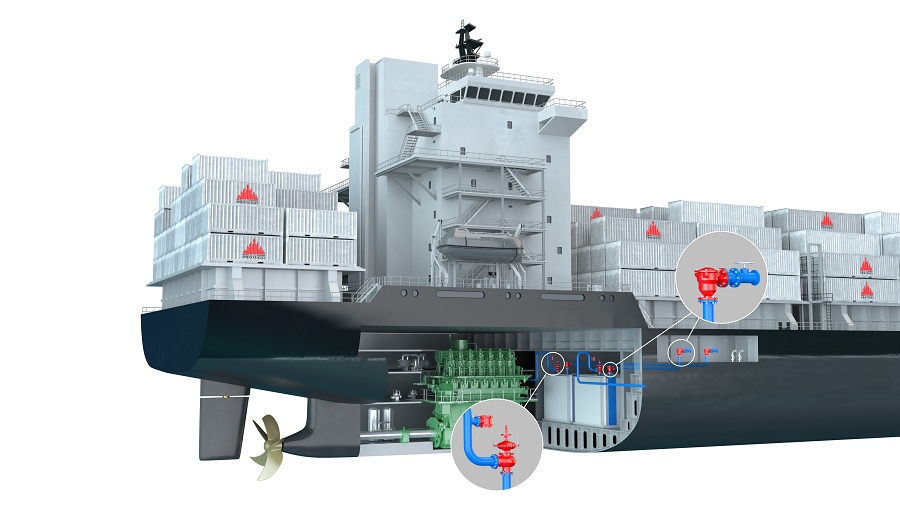

Safety of Ships

Explosion protection for methyl/ethyl alcohol as fuel according to IMO MSC.1/Circ.1621

Please note that the solutions presented here are just examples; we work closely with our customers to provide tailored safety solutions for their specific operational needs and to comply with local regulations and standards.

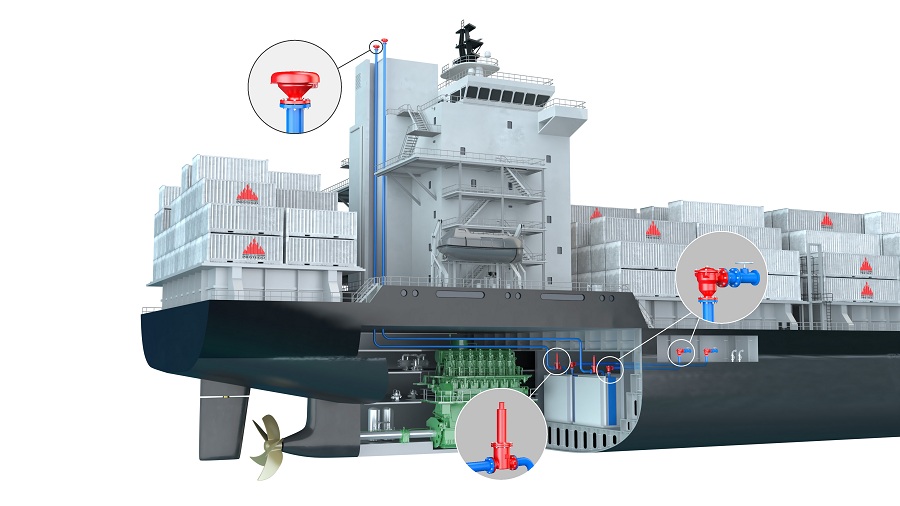

Pressure / Vacuum Relief Valve on the tank combined with Flame Arrester on the vent mast

- Protection of the fuel tank with in-line Pressure and Vacuum Relief Valve PROTEGO® DV/ZT-F-S in combination with an end-of-line Flame Arrester BE/HR-E on the vent mast

- The vapor-return-line to the bunkering station is protected with a Detonation Flame Arrester PROTEGO® DR/ES

- PROTEGO® Flame Arresters are type approved as per EN ISO 16852 and conform to ISO/IEC 80079-49 respectively to prevent against the impact of atmospheric deflagration and endurance burning

- PROTEGO® Flame Arresters are type approved for endurance burning with alcohols as required by the operating conditions

- Type approvals as per classification authority upon request

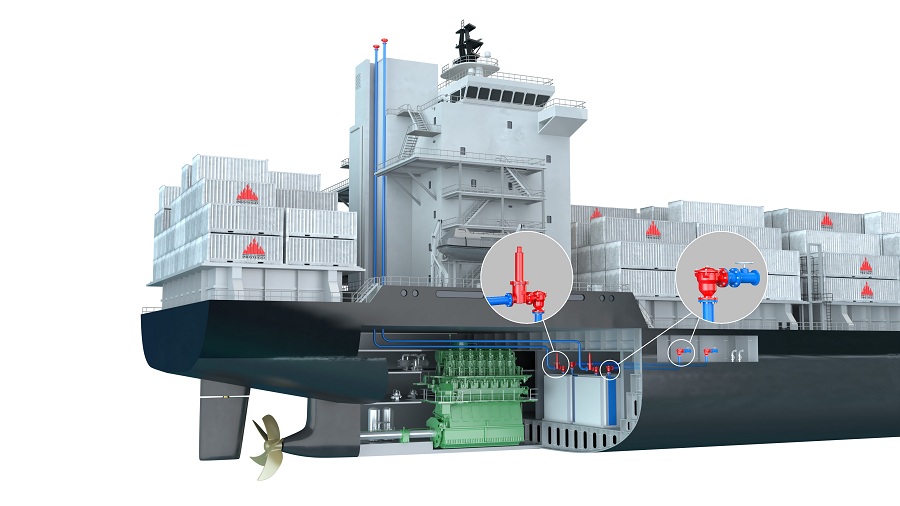

P/V Valve combined with Detonation Arrester on the Tank

- Protection of the fuel tank with in-line Pressure and Vacuum Relief Valve PROTEGO® DV/ZT-F-S in combination with a detonation-proof Flame Arrester PROTEGO® DR/ES

- The vapor-return-line to the bunkering station is protected with a Detonation Flame Arrester PROTEGO®DR/ES

- PROTEGO® Flame Arresters are type approved as per EN ISO 16852 and conform to ISO/IEC 80079-49 respectively for explosion group IIA for methanol and IIB1 or higher for ethanol

- PROTEGO® Flame Arresters are type approved and tested for elevated pressures and temperatures as required by the operating conditions

- Type approvals as per classification authority upon request

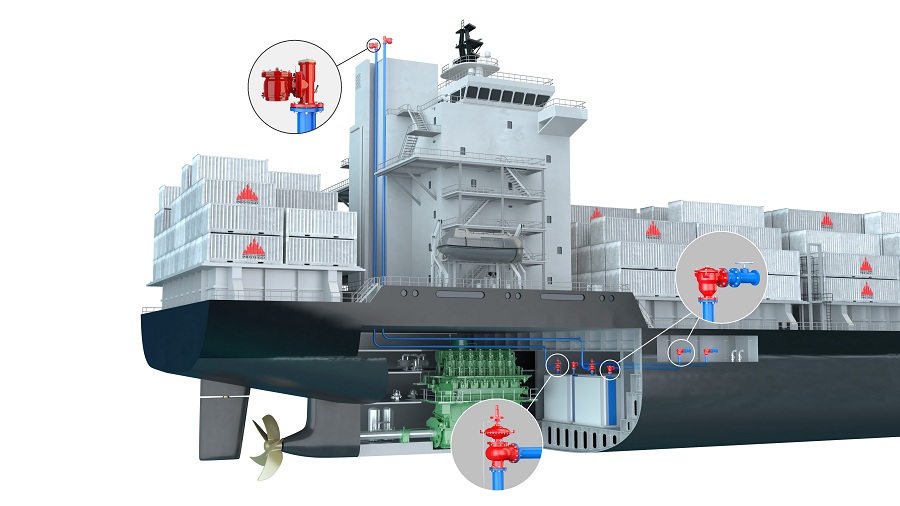

Jet-Valve combined with Vacuum Relief Valve

- Protection of the fuel tank with a high velocity Pressure Relief Valve PROTEGO® DE/S in combination with Vacuum Relief Valve PROTEGO®SV/E-S

- The vapor-return-line to the bunkering station is protected with a Detonation Flame Arrester PROTEGO®DR/ES

- PROTEGO® Valves are type approved as per EN ISO 16852 and conform to ISO/IEC 80079-49 respectively and ISO 15364

- Type approvals as per classification authority upon request

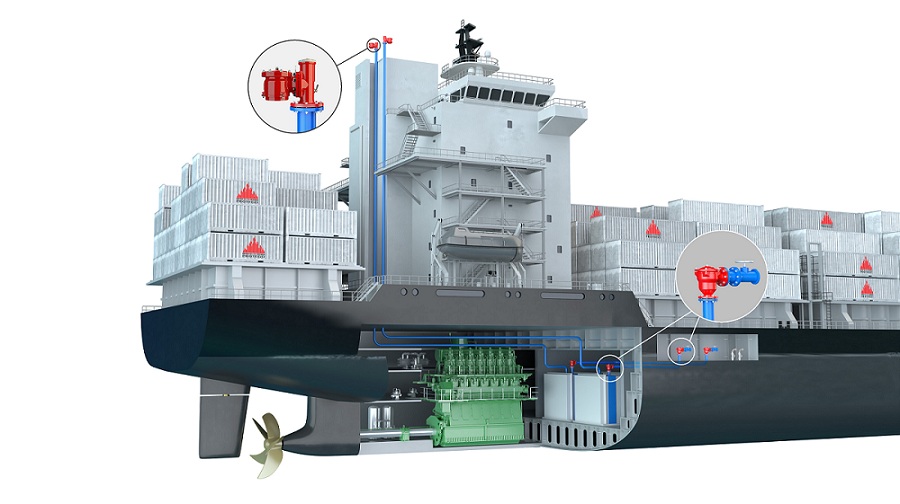

Jet-valve with Vacuum Relief Valve in combination with pilot-operated Pressure/Vacuum Relief Valve

- The vapor-return-line to the bunkering station is protected with a Detonation Flame Arrester PROTEGO® DR/ES

- Protection of the fuel tank with a redundant in-line combination of pilot-operated Pressure / Vacuum Relief Valve PROTEGO® VN-A-PCPF-S and a high-velocity Pressure Relief Valve PROTEGO® DE/S in combination with Vacuum Relief Valve PROTEGO® SV/E-S at the vent mast

- PROTEGO® Valves are type approved as per EN ISO 16852 and conform to ISO/IEC 80079-49 respecti vely and ISO 15364

- Type approvals as per classification authority upon request

Pilot-operated Pressure/Vacuum Relief Valve with additional Vacuum Relief Valve - vapor discharge through outlets underwater

- Protection of the fuel tank with a pilot-operated Pressure / Vacuum Relief Valve PROTEGO® VN-A-PCPF-S and a Vacuum Relief Valve PROTEGO® SV/E-S

- The vapor-return-line to the bunkering station is protected with a Detonation Flame Arrester PROTEGO® DR/ES

- PROTEGO® Valves are type approved as per EN ISO 16852 and conform to ISO/IEC 80079-49 respectively

- Type approvals as per classification authority upon request

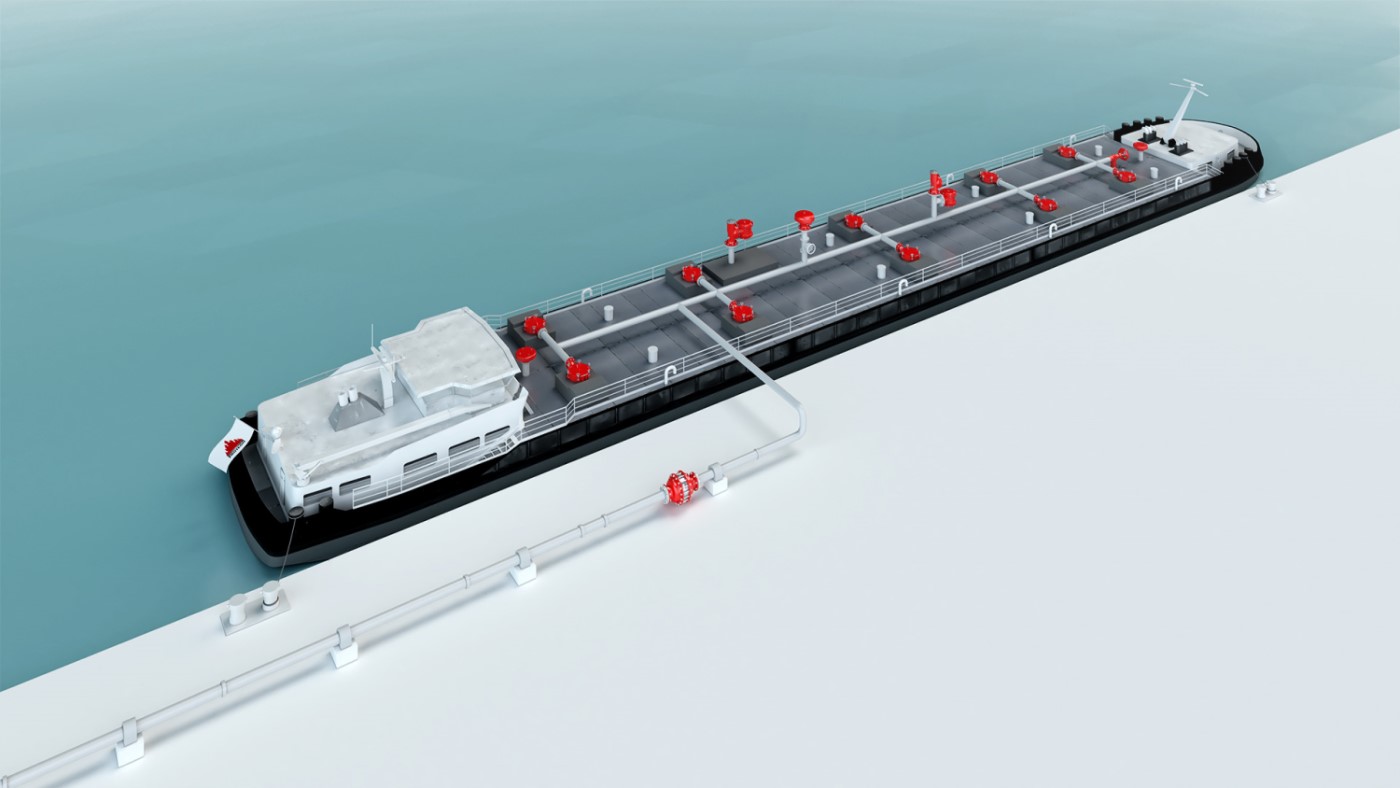

Protection of inland waterway vessels

- Protection of storage tanks; PROTEGO® BR/TS

- Protection of storage tanks, slop tanks (residual tanks), vapour manifold; PROTEGO® DE/S

- Protection of storage tanks, slop tanks (residual tanks), vapour manifold; PROTEGO® SV/E-S

- Connected to vapour manifold (with e.g. ball valve); PROTEGO® BE/HR-E

- Protection of coffer dams; PROTEGO® LH/AD(-S)

- Vapour manifold; PROTEGO® ZE/WU, ZE/TK

- Protection of vapour return pipeline; PROTEGO® DA-SB

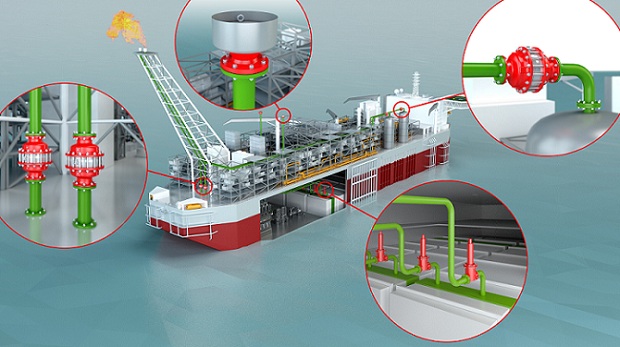

Protection of FPSOs (Floating Production, Storage and Offloading)

- Storage tanks in the hull of the ship are protected with Pressure and Vacuum Relief Valves PROTEGO® DV/ZT-F.

- Flares and cold flares (also called “vent posts”) are protected with in-line Detonation Flame Arresters PROTEGO® DA-SB. Temperature sensors for these devices are recommended.

- Storage tanks (mainly chemicals) on the top of the ships are protected with end-of-line Deflagration Flame Arresters PROTEGO® LH/AD-S (specially developed for ship applications), end-of-line Deflagration Flame Arresters PROTEGO® LH/AD, or in-line Detonation Flame Arresters PROTEGO® DA-SB.

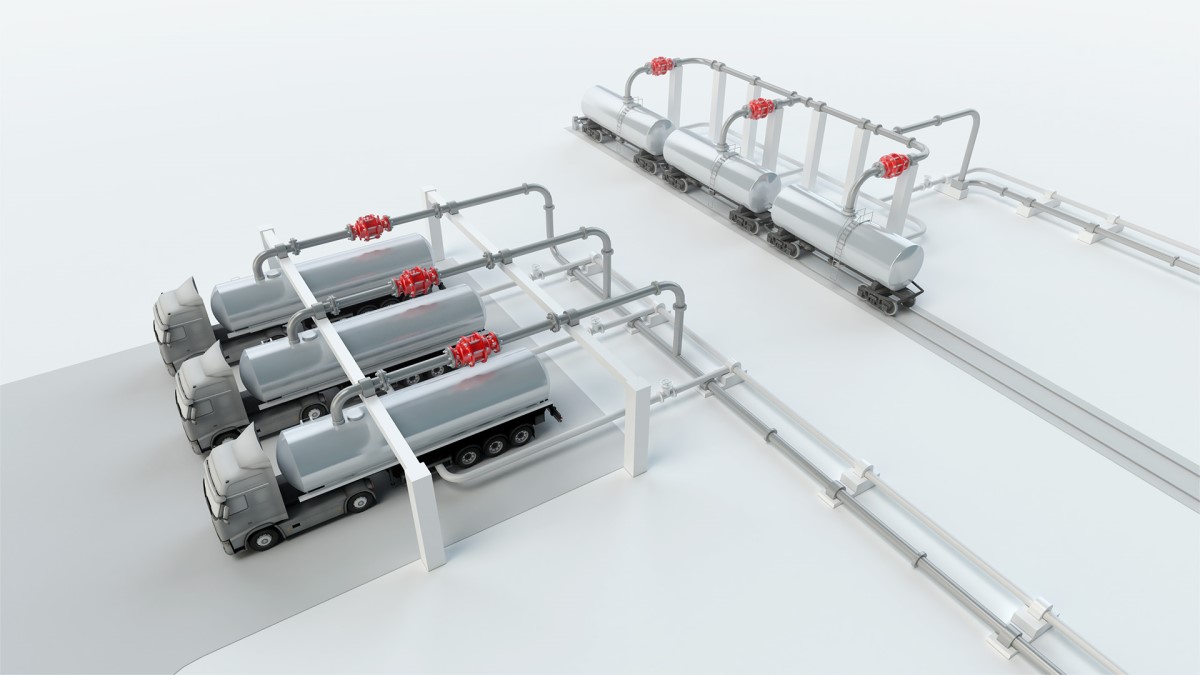

Protection of tankers with Flame Arresters and Valves

- Equipping tankers for flammable products/chemical tankers with BR/TS detonation flame arresters on the individual tank, DE/S endurance burning-proof high-velocity vent valves and SV/E-S explosion-proof vacuum flame arresters.

- Detonation-proof connection of the vapour recovery line at the loading terminal for flammable liquids with DA-SB detonation flame arresters.

What about your application?

Contact our specialists for your individual requirements.