BE/HK-E-IIB

Deflagration Flame Arrester, endurance burning proof, End-of-Line

- endurance burning protection for alcohols and hydrocarbons with MESG ≥ 0,5mm.

- weather hood protects the PROTEGO<® flame arrester unit against environmental impact, such as nesting animals and weather conditions

- in case of fire, the weather hood opens, allowing the flame to be seen from a far distance

- centrally aligned melting element is resistant to chemicals

- modular design enables replacement of individual FLAMEFILTER®discs

- trouble-free maintenance

- provides protection against atmospheric deflagrations and endurance burning

- cost-effective spare parts

Function and Description

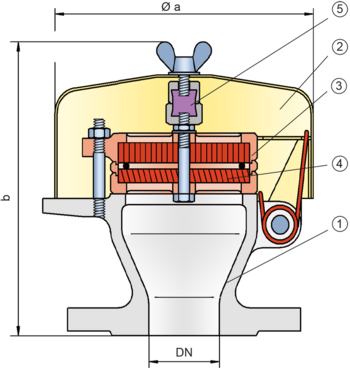

The PROTEGO® BE/HK-E end-of-line deflagration flame arrester was specifically developed for vessels which are not pressurized and store Ethanol or other alcohols. The combustion of alcohol requires a modified flame arrester element design to provide protection against endurance burning. In addition, the device provides protection against atmospheric deflagration. It is typically installed on in - breathing and out-breathing vent lines to prevent flame transmission into the vessel or plant caused by endurance burning or atmospheric deflagration.The PROTEGO® BE/HK-E consists of the housing (1), a weather hood (2), and the PROTEGO® flame arrester unit (3). During normal operation, the metal weather hood is in a closed position. If a stabilized flame burns on the flame arrester element surface, the melting element (5), located in a center position, will melt, and the spring- loaded weather hood will open. The PROTEGO® flame arrester unit consists of two FLAMEFILTER ® discs (4), which are installed in a FLAMEFILTER® casing. The PROTEGO® BE/HK-E end-of-line deflagration flame arrester is available for alcohols and other substances with MESG ≥ 0,5mm.

The standard design can be used for operating temperatures up to +60°C / 140°F.

EU conformity according to the currently valid ATEX directive. Approvals according to other national/international regulations on request.

Dimensions

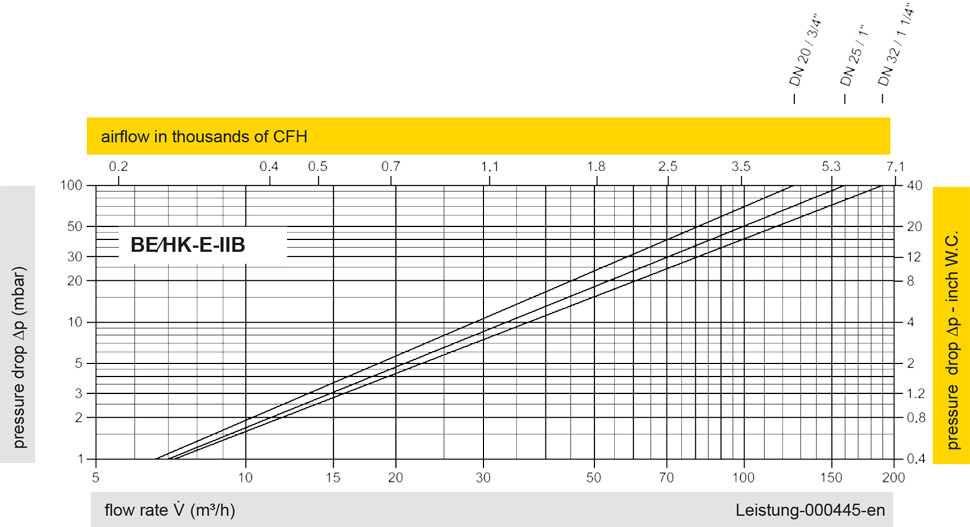

To select the nominal size (DN), please use the flow capacity charts on the following pages

| DN | 20 / ¾" | 25 / 1" | 32 / 1¼" | ||||

| a | 163 / 6.42 | 163 / 6.42 | 163 / 6.42 | ||||

| b | 180 / 7.09 | 177 / 6.97 | 177 / 6.97 |

Material selection for housing

| Design | B | C |

| Housing | Steel | Stainless Steel |

| Weather Hood | Steel | Stainless Steel |

| Flame arrester unit | A | A, B |

Material combinations of flame arrester unit

| Design | A | B |

| FLAMEFILTER® cage | Stainless Steel | Stainless Steel |

| FLAMEFILTER® | Stainless Steel | Hastelloy |

| Spacer | Stainless Steel | Hastelloy |

Selection of explosion group

| MESG | Expl. Gr. (IEC / CEN) | Gas Group (NEC) |

| ≥ 0,5 mm | IIB | – |

Flange connection type

| EN 1092-1; Form B1 |

| ASME B16.5 CL 150 R.F. |

Design Types and Specifications

There are two different designs:

End-of-line deflagration flame arrester, basic design | BE/HK-E - – |

End-of-line deflagration flame arrester with heating jacket | BE/HK-E - H |

Special designs available on request

Flow Capacity Chart

The flow capacity charts have been determined with a calibrated and TÜV certified flow capacity test rig. Volume flow V in (m³/h) and CFH refer to the standard reference conditions of air ISO 6358 (20°C, 1bar). For conversion to other densities and temperatures refer to Sec. 1: “Technical Fundamentals”.