BE/HR-E-IIB3

Calota de respiro à prova de deflagração e combustão contínua

- endurance burning protection for alcohols and hydrocarbons up to explosion group IIB3

- specially developed for sea going vessels but also useful for inland navigation vessels and on shore systems

- weather hood protects against environmental impact (i.e. weather, bird nests, etc.)

- weather hood opens and signals the impact of a flame

- fusible link is resistant against chemicals

- modular design allows replacement of single FLAMEFILTER®

- protection against atmospheric deflagration and endurance burning

- modular design results in low spare part cost

Função e descrição

The PROTEGO® BE/HR-E-IIB3 end-of-line deflagration flame arrester was specifically developed for vessels which are not pressurized and store Ethanol or other alcohols. The combustion of alcohol requires a modified flame arrester element design to provide protection against endurance burning. In addition, the device provides protection against atmospheric deflagration. Main application area is on suction and vent lines, for sea going vessels but also useful for inland navigation vessels with the goal to prevent flame transmission caused by endurance burning or atmospheric deflagration.

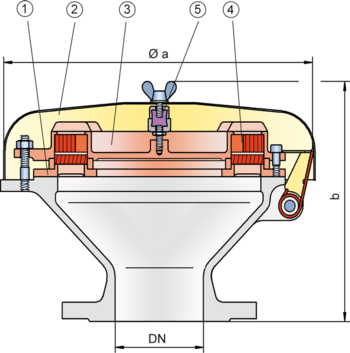

The PROTEGO® BE/HR-E-IIB3 consists of a housing (1), a weather hood (2) and the PROTEGO® flame arrester unit (3). During normal operation, the metal weather hood is in a closed position. If a flame burns on the flame arrester element surface, the fusible link (5), located in a center position, will melt and let the spring loaded weather hood move into the open position. The PROTEGO® flame arrester unit consists of two FLAMEFILTER® discs (4), which are installed in a FLAMEFILTER® casing.

The PROTEGO® BE/HR-E end-of-line deflagration flame ar-rester is available for hydrocarbons for explosion group IIB3 (MESG ≥ 0,65 mm) and alcohols.

The standard design can be used for operating temperatures up to +60°C / 140°F.

EU conformity according to the currently valid ATEX directive. Approvals according to other national/international regulations on request. Approved according to IMO MSC/Circular 677 as well as IMO MSC.1/Circular 1324 and 1325.

Tabela de dimensões

To select the nominal size (DN), please use the flow capacity charts on the following pages

| DN | 80 / 3" | 100 / 4" |

| a | 353 / 13.90 | 353 / 13.90 |

| b | 250 / 9.84 | 250 / 9.84 |

Seleção do material do corpo

| Design | B | C |

| Housing | Steel | Stainless Steel |

| Weather Hood | Steel | Stainless Steel |

| Flame arrester unit | A | A, C |

Combinações de material do conjunto abafador de chamas

| Design | A | C |

| FLAMEFILTER® cage | Stainless Steel | Stainless Steel |

| FLAMEFILTER® | Stainless Steel | Hastelloy |

| Spacer | Stainless Steel | Hatelloy |

Seleção do grupo de explosão

| MESG | Expl. Gr. (IEC / CEN) | Gas Group (NEC) |

| ≥ 0,65 mm | IIB3 | C |

Tipo de conexão flangeada

| EN 1092-1; Form B1 |

| ASME B16.5 CL 150 R.F. |

Versão e especificação

Estão disponíveis duas versões:

Calota de respiro em versão básica | BE/HR-E - – |

Calota de respiro com camisa de aquecimento | BE/HR-E - H |

Outros dispositivos especiais sob solicitação

Diagrama de vazão

Este diagrama de vazão foi determinado em uma bancada de medição de vazão calibrada e certificada pela TÜV. A vazão V em m³/h se refere ao estado técnico padrão de ar, conforme ISO 6358 (20°C, 1bar). Para conversão em outras densidades e temperaturas, veja o cap. 1: Bases técnicas.