FA-G

In-Line Deflagration Flame Arrester concentric design, bidirectional

- different application possibilities

- modular design

- the individual FLAMEFILTER® can be quickly removed and installed

- threaded connection for direct mounting into pipeline

- bi-directional flame transmission proof design

- protects against deflagrations for all explosion groups

- use of temperature sensors for G 1½ and G 2 is possible

- cost efficient spare parts

Función y Descripción

The compact design of the PROTEGO® FA-G in-line deflagration flame arrester makes it the state-of-the-art technology for installation in pipes with diameters of up to 2”. The devices are installed with minimal distance to the burner to prevent flashback into the fuel feed lines. When installing the deflagration flame arrester, make sure that the distance between potential ignition sources and the location of the installed device does not exceed the L/D ratio (pipe length/pipe diameter) for which the device was approved. As per EN ISO 16852, the L/D ratio is limited to (L/D)max ≤ 50 for deflagration flame arresters of explosion groups IIA and IIB3 (NEC groups D and C {MESG ≥ 0.65 mm}) and to (L/D)max ≤ 30 for explosion group IIC (NEC group B).

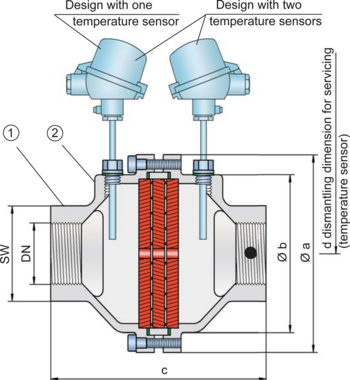

The in-line deflagration flame arrester is symmetrical and offers bi-directional flame transmission protection. The device consists of two housing parts (1) and a PROTEGO® flame arrester unit or a FLAMEFILTER® (2) and spacers in the center. The number of FLAMEFILTER® discs and their gap size depend on the operating conditions, such as the temperature, pressure, explosion group, and the composition of the fluid. The PROTEGO® FA-G series in-line deflagration flame arresters is available for explosion groups IIA, IIB3, and IIC (NEC groups D, C {MESG ≥ 0.65 mm} and B).

The standard design can be used with an operating temperature of up to+60°C / 140°F and an absolute operating pressure acc. to table 3. Devices with special approval for higher pressures and higher temperatures are available upon request.

EU conformity according to the currently valid ATEX directive. Approvals according to other national/international regulations on request.

Dimensiones

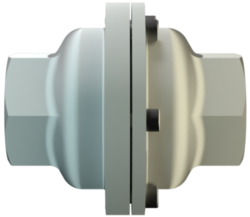

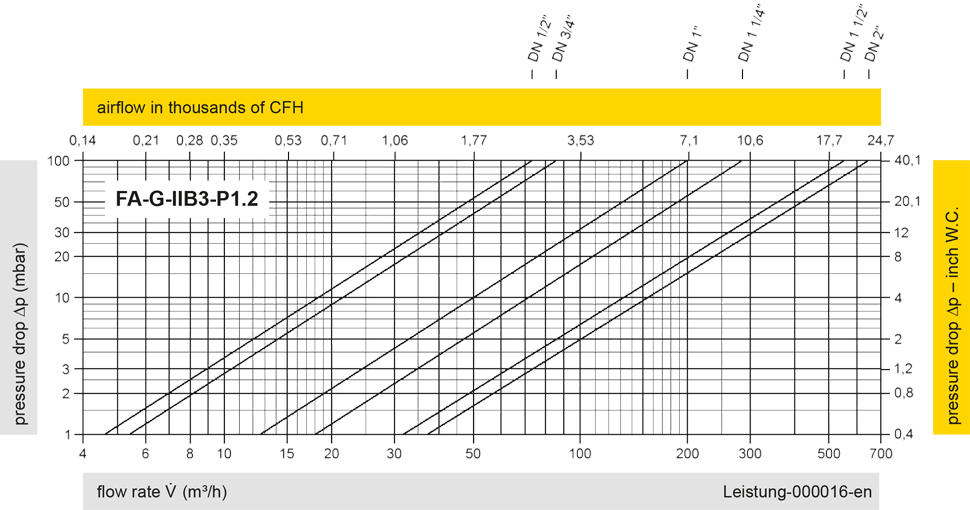

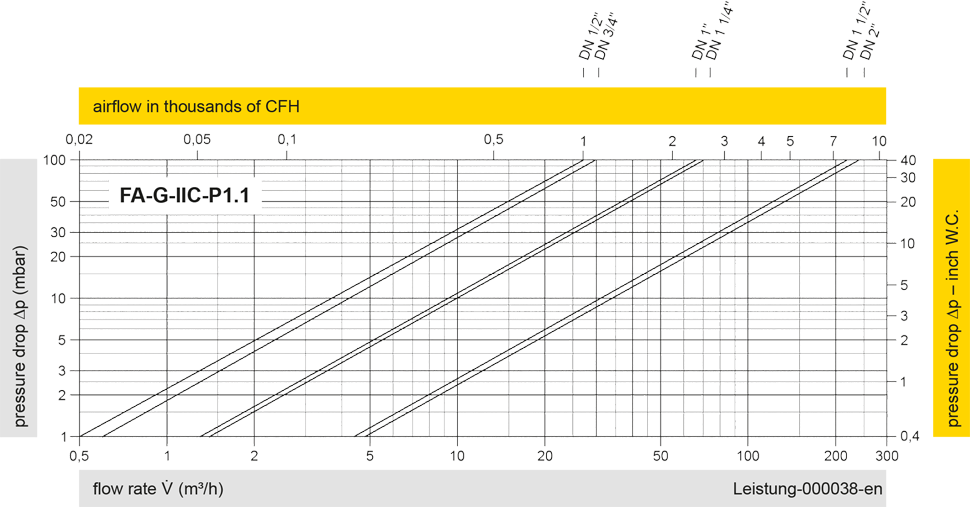

To select the nominal size (DN), use the flow capacity charts on the following pages

| DN | G ½" | G ¾" | G 1" | G 1 ¼" | G 1 ½" | G 2" |

| a | 80 / 3.15 | 80 / 3.15 | 100 / 3.94 | 100 / 3.94 | 155 / 6.10 | 155 / 6.10 |

| b | 55 / 2.17 | 55 / 2.17 | 76 / 2.99 | 76 / 2.99 | 124 / 4.88 | 124 / 4.88 |

| c (IIA bis IIB3) | 100 / 3.94 | 100 / 3.94 | 110 / 4.33 | 110 / 4.33 | 170 / 6.69 | 170 / 6.69 |

| c (IIB und IIC) | 112 / 4.41 | 112 / 4.41 | 122 / 4.80 | 122 / 4.80 | 170 / 6.69 | 170 / 6.69 |

| d | — | — | — | — | 400 / 15.75 | 400 / 15.75 |

| SW | 32 / 1.26 | 32 / 1.26 | 50 / 1.97 | 50 / 1.97 | 75 / 2.95 | 75 / 2.95 |

Selección de materiales

| Design | B | C |

| Housing | Stainless Steel | Hastelloy |

| Gasket | PTFE | PTFE |

| FLAMEFILTER®* | Stainless Steel | Hastelloy |

Selección del grupo de explosión

| MESG | Expl. Gr. (IEC / CEN) | Gas Group (NEC) |

| > 0,90 mm | IIA | D |

| ≥ 0,65 mm | IIB3 | C |

| < 0,50 mm | IIC | B |

Selección de la máxima presión de operación

| Expl. Gr | DN | G ½" | G ¾" | G 1" | G 1¼" | G 1½" | G 2'' |

| IIA | Pmax | 1,4 / 20.3 | 1,4 / 20.3 | 1,4 / 20.3 | 1,4 / 20.3 | 1,5 / 21.7 | 1,5 / 21.7 |

| IIB3 | Pmax | 1,2 / 17.4 | 1,2 / 17.4 | 1,2 / 17.4 | 1,2 / 17.4 | 1,2 / 17.4 | 1,2 / 17.4 |

| IIC | Pmax | 1,1 / 15.9 | 1,1 / 15.9 | 1,1 / 15.9 | 1,1 / 15.9 | 1,1 / 15.9 | 1,1 / 15.9 |

Especificación de la máx. temperatura de operación

| ≤ 60°C / 140°F | Tmaximum allowable operating temperature in °C |

| - | Designation |

Tipo de conexión

| Pipe thread DIN ISO 228-1 | DIN |

Modelo y especificación

There are three different designs:

Basic in-line deflagration flame arrester (G ½" to 2") | FA-G - – |

In-line deflagration flame arrester with integrated temperature sensor* for additional protection against short-time burning from one side (G 1½" to 2") | FA-G - T |

In-line deflagration flame arrester with two integrated temperature sensors* for additional protection against short-time burning from both sides (G 1½" to 2") | FA-G - TB |

Additional special devices available upon request

*Resistance thermometer for device group II, category (1) 2 (GII cat. (1) 2)

Diagrama de flujo volumétrico

Los diagramas de flujo volumétrico han sido determinados con un banco de pruebas de caudal calibrado y certifi - cado por TÜV. El flujo volumétrico V. en [m³/h] y el CFH se refi eren a las condiciones estándar de referencia de aire según ISO 6358 (20°C, 1bar). La conversión a otras densidades y temperaturas están referidas en el Vol. 1: “Fundamentos Técnicos”.