LDA-WF(W)

In-Line Liquid Detonation Flame Arrester for filling and drain lines - external installation

- easily accessible due to external installation

- siphon protection offers increased safety

- low risk of contamination

- low pressure loss

- provides protection against deflagrations and stable detonations

- useable for nearly all flammable liquids

- meets TRGS* requirements

Function and Description

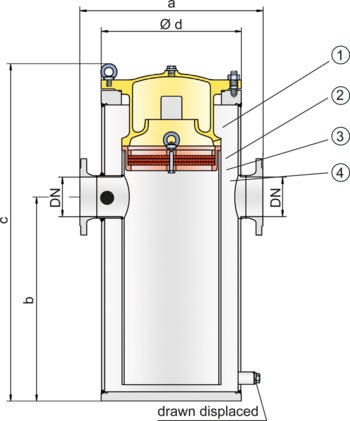

The PROTEGO® LDA-WF(W) series of liquid detonation flame arresters was developed for storage container filling lines that are not continuously filled with product and sometimes contain a combustible mixture. The integrated siphon protection (1) with PROTEGO® flame arrester unit (2) additionally prevents the liquid, in which the lines are immersed, from being siphoned off while the container is being drained. The PROTEGO® flame arrester unit consists of several FLAMEFILTER® discs (3) and spacers firmly held in a FLAMEFILTER® casing (4). The number of FLAMEFILTER® discs and their gap size depends on the arrester’s intended use. The device is installed outside the container in the filling and drain lines. If the explosive atmosphereis ignited, the device prevents the combustion from traveling into the tank. The PROTEGO® LDA-WF(W) series of liquid detonation flame arresters combines the classic PROTEGO® flame arrester design with the siphon principle in which the liquid product serves as a barrier to flame propagation.

When a highly accelerated pipe deflagration or detonation occurs, the combustion pressure and flame propagation speed are substantially reduced, converted into a low-energy deflagration, and then stopped by the remaining immersion liquid and the PROTEGO® flame arrester.

The application range for the device is a product vapor/air mixture temperature of up to +60°C / 140°F and an absolute pressure up to 1.1 bar / 15.9 psi. Devices with special approval for higher temperatures are available upon request. This covers all possible operating conditions of empty lines for flammable liquids. The liquid detonation arrester is designed for pressures of up to 10 bar / 145 psi, resists explosion pressure, and provides protection for almost all flammable liquids. The device is approved for explosion groups IIA to IIB3 (NEC group D to C MESG ≥ 0.65 mm). Special designs with a cleaning cover for highly viscous liquids can be provided.

Type-approved in accordance with the current ATEX Directive and EN ISO 16852, as well as other international standards.

Dimensions

To select the nominal size (DN), please use the flow capacity chart on the following pages

| DN | 25 / 1" | 32 / 1¼“ | 40 / 1½“ | 50 / 2" | 65 / 2½“ | 80 / 3" | 100 / 4" | 125 / 5" | 150 / 6" | 200 / 8" | 250 / 10" |

| a | 250 / 9.84 | 250 / 9.84 | 350 / 13.78 | 350 / 13.78 | 450 / 17.72 | 450 / 17.72 | 500 / 19.69 | 600 / 23.62 | 600 / 23.62 | 700 / 27.56 | 900 / 35.43 |

| b | 325 / 12.80 | 325 / 12.80 | 415 / 16.34 | 415 / 16.34 | 535 / 21.06 | 535 / 21.06 | 600 / 23.62 | 915 / 36.02 | 915 / 36.02 | 1090 / 42.91 | 1300 / 51.18 |

| c | 475 / 18.70 | 475 / 18.70 | 605 / 23.82 | 605 / 23.82 | 831 / 32.72 | 831 / 32.72 | 936 / 36.58 | 1340 / 52.76 | 1340 / 52.76 | 1520 / 59.84 | 1750 / 68.90 |

| d | 150 / 5.91 | 150 / 5.91 | 210 / 8.27 | 210 / 8.27 | 275 / 10.83 | 275 / 10.83 | 325 / 12.80 | 460 / 18.11 | 460 / 18.11 | 510 / 20.08 | 610 / 24.02 |

Material selection for housing

| Design | A | B |

| Housing | Steel | Stainless Steel |

| Shock absorber | Steel | Stainless Steel |

| Gasket (shock absorber) | FPM | PTFE |

| Gasket (locking screw) | PTFE | PTFE |

| Flame arrester unit | A | A |

Material selection for flame arrester unit

| Design | A |

| FLAMEFILTER® cage | Stainless Steel |

| FLAMEFILTER®* | Stainless Steel |

| Spacer | Stainless Steel |

Selection of explosion group

| MESG | Expl. Gr. (IEC / CEN) | Gas Group (NEC) |

| > 0,90 mm | IIA | D |

| ≥ 0,65 mm | IIB3 | C |

Specification of max. operating temperature

| ≤ 60°C / 140°F | Tmaximum allowable operating temperature in °C |

| - | Designation |

Flange connection type

| EN 1092-1; Form B1 |

| ASME B16.5 CL 150 R.F. |

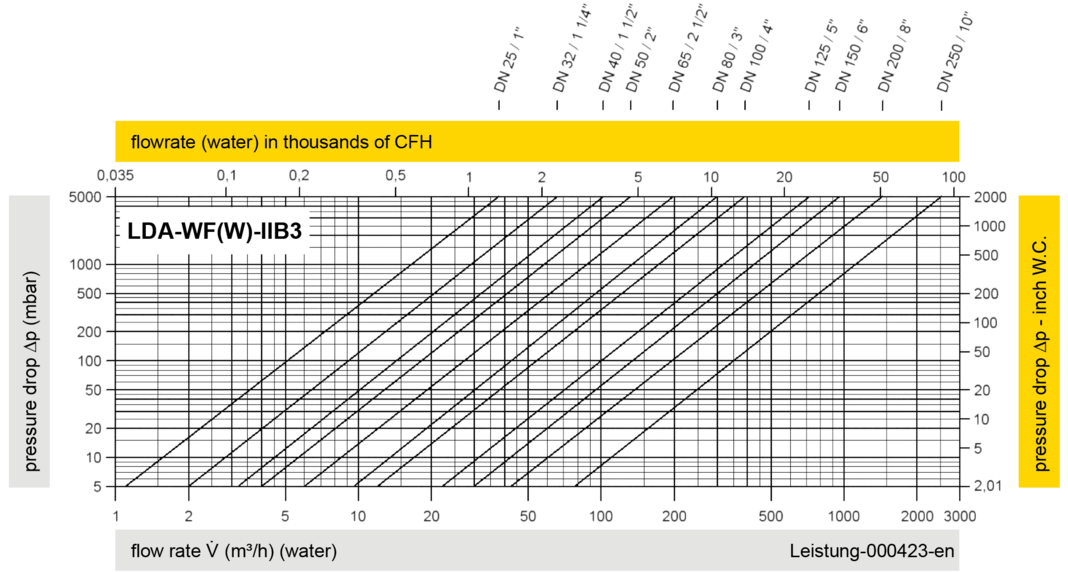

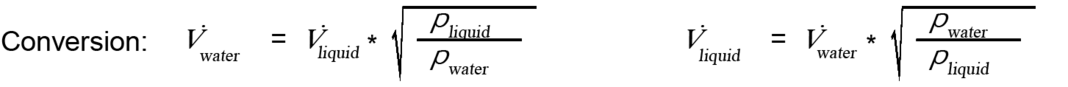

Flow Capacity Chart

The volume flow V in m³/h was determined with water according to DIN EN 60534 at a temperature Tn = 20°C and an atmospheric pressure pn = 1,013 bar, kinematic viscosity v = 10-6 m²/s

To avoid electrostatic charge of flammable liquids the maximum flow is limited (refer to TRGS 727, CENELEC-Report CLC/TR 60079-32-1).