EV/VS, EV/VD

Flame Arrester Unit for vacuum pumps, compressors and blowers

- cost-effective alternative to complete flame arresters with flange connection

- customized protection for vacuum pumps, blowers and compressors

- modular design provides every user with the optimal flame arrester unit

- flexible design parameters result in lowest pressure drops

- modular flame arrester unit enables individual FLAMEFILTER® to be replaced and cleaned

- modular design reduces spare parts cost

- worldwide, long-term availability of spare parts in different materials

Function and Description

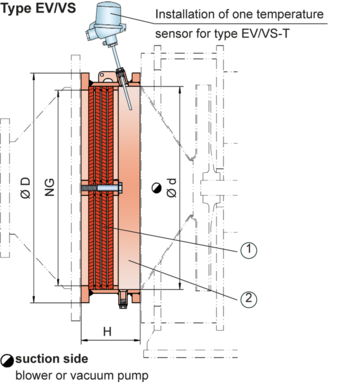

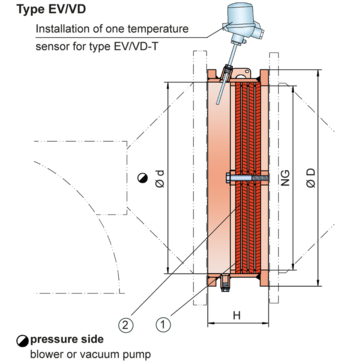

EV/VS and EV/VD flame arrester units provide manufacturers of vacuum pumps, blowers and compressors with a cost-effective protection for their machines. The high flow velocities in the small gaps of these machines can lead to undesirable ignitions within the housing. One of the safest measures against explosion propagation are flame arrester units that are installed on the inlet and outlet side of the machines. EV/VS for inlet (vacuum side) and EV/VD for outlet (pressure side) are flame arrester units without housing. They are designed modular providing each manufacturer of blowers, vacuum pumps or similar devices the option of using optimized, adapted, and cost-effective flame arrester units. Our expert technical staff will assist you with the proper selection of the devices as well as execution of type testing.

EV/VS and EV/VD flame arrester units are modular in design and consist of several FLAMEFILTER® (1) installed within the FLAMEFILTER® cage (2). The number of FLAMEFILTER® and the gap size depend on the intended use. Both types have a threaded nozzle for temperature sensors. EV/VS and EV/VD flame arrester units are available for explosion groups from IIC to IIA (NEC groups B to D) and special gases such as ethylene oxide.

Dimensions

Dimensions in mm / inchesMaterial flame arrester unit

| Design | A | B | C |

| FLAMEFILTER® cage | Steel | Stainless steel | Hastelloy |

| Gasket | PTFE | PTFE | PTFE |

| FLAMEFILTER® Set | A, B | B | C |

Material combinations of flame arrester unit

| Design | A | C | D |

| FLAMEFILTER® * | Stainless steel | Stainless steel | Hastelloy |

| Spacers | Stainless steel | Stainless steel | Hastelloy |

Selection of FLAMEFILTER® gap

| FLAMEFILTER® gap |

| 0.7 mm |

| 0.5 mm |

| 0.3 mm |

| 0.2 mm |

Design Types and Specifications

There are four different designs:

Flame arrester unit for the inlet side, basic design | EV/VS – |

Flame arrester unit for the inlet side with integrated temperature sensor* for additional protection against short-time burning on one side | EV/VS- T |

Flame arrester unit for the pressure side, basic design | EV/VD – |

Flame arrester unit for the pressure side with integrated temperature sensor* for additional protection against short-time burning on one side | EV/VD- T |

*Resistance thermometer for device group II, category (1) 2 (GII cat. (1) 2)