EB

Deflagration Flame Arrester, endurance burning proof, End-of-Line

- weather hood provides protection against environmental impact (harsh weather conditions, bird nests, etc.)

- weather hood will open and signal the impact of a flame

- protection against atmospheric deflagration and endurance burning of pure hydrocarbons

- fusible link is resistant against chemicals

- modular design allows replacement of single FLAMEFILTER®

- easy maintenance without disassembling of the FLAMEFILTER®

- modular design results in low spare part costs

Function and Description

The PROTEGO® EB end-of-line deflagration flame arrester provides protection against atmospheric deflagration and long-lasting stabilized flames, called endurance burning. The device is typically installed on vent lines of vessels and plant equipment which is not pressurized. The device prevents flame transmission from endurance burning or atmospheric deflagration into the vessel or plant.

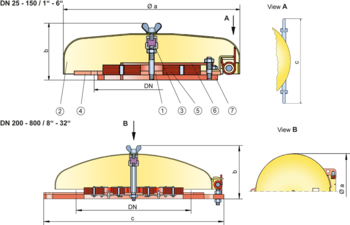

The PROTEGO® EB-IIA consists of the PROTEGO® flame arrester unit (1) and the metal weather hood (2). During normal operation, the metal weather hood is in a closed position. If a stabilized flame burns on the flame arrester element surface, the melting element (3), located in a center position, will melt and let the spring-loaded weather hood move into the open position. The PROTEGO® flame arrester unit consists of one or more FLAMEFILTER® (5), which are installed in a FLAMEFILTER® casing (4), a fixation element (6) and an insert ring (7). The FLAMEFILTER® gap size, height, and quantity depend on the device’s intended use.

The PROTEGO® EB series end-of-line deflagration flame arrester is available for substances from explosion group IIA and IIB (NEC group D and B).

The standard design can be used with an operating temperature of up to +60°C / 140°F. Devices with special approval for higher temperatures are available upon request.

Type-approved in accordance with the current ATEX Directive and EN ISO 16852, as well as other international standards.

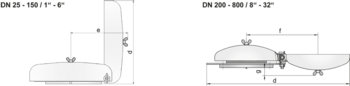

Dimensions DN 25 - 150 for EB-IIA and IIB

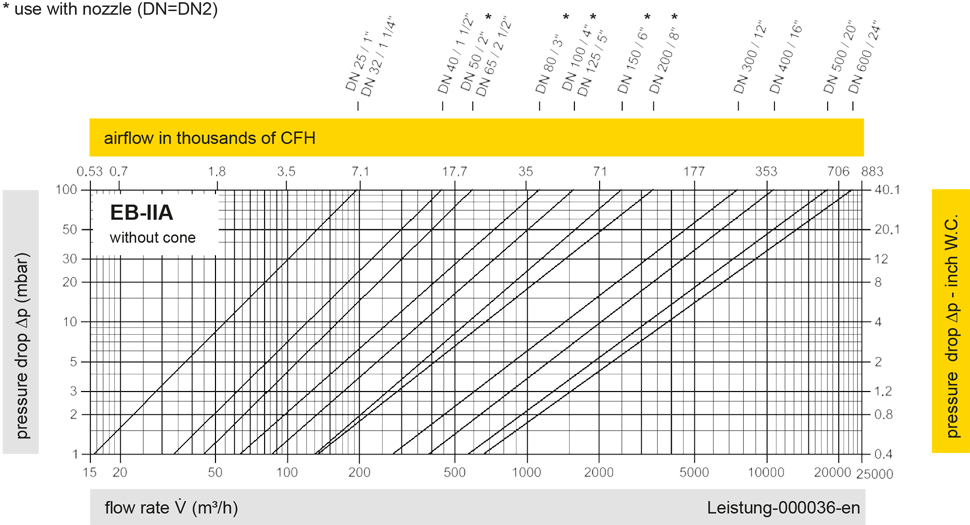

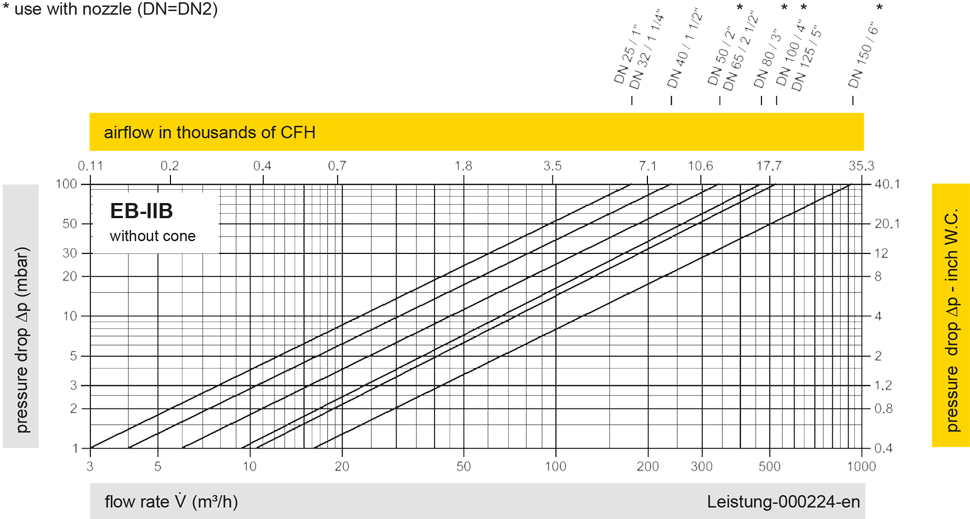

To select the nominal size (DN), please use the flow capacity chart on the following page

| DN | 25 / 1" | 32 / 1¼“ | 40 / 1½“ | 50 / 2“ | 65 / 2½“ | 80 / 3“ | 100 / 4" | 125 / 5" | 150 / 6" |

| a | 218 / 8.58 | 218 / 8.58 | 218 / 8.58 | 218 / 8.58 | 218 / 8.58 | 353 / 13.90 | 353 / 13.90 | 353 / 13.90 | 353 / 13.90 |

| b | 113 / 4.45 | 113 / 4.45 | 113 / 4.45 | 113 / 4.45 | 113 / 4.45 | 113 / 4.45 | 113 / 4.45 | 113 / 4.45 | 113 / 4.45 |

| c | 232 / 9.13 | 232 / 9.13 | 232 / 9.13 | 232 / 9.13 | 232 / 9.13 | 306 / 12.05 | 306 / 12.05 | 306 / 12.05 | 306 / 12.05 |

| d | 222 / 8.74 | 222 / 8.74 | 222 / 8.74 | 222 / 8.74 | 222 / 8.74 | 355 / 13.98 | 355 / 13.98 | 355 / 13.98 | 355 / 13.98 |

| e | 217 / 8.54 | 217 / 8.54 | 217 / 8.54 | 217 / 8.54 | 217 / 8.54 | 322 / 12.68 | 322 / 12.68 | 322 / 12.68 | 322 / 12.68 |

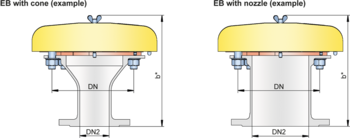

| EB-IIA and IIB with cone / nozzle** | |||||||||

| DN | 50 / 2" | 80 / 3" | 100 / 4" | 150 / 6" | |||||

| DN2 | ≤50 / 2“ | ≤80 / 3“ | ≤100 / 4 | ≤150 / 6“ | |||||

| b* | 238 / 9.37 | 263 / 10.35 | 383 / 15.08 | 313 / 12.32 | |||||

| Dimensions DN 200 - 800 / 8“ - 32“ for EB-IIA | |||||||||

| DN | 200 / 8" | 300 / 12" | 400 / 16" | 500 / 20" | 600 / 24" | 800 / 32“ | |||

| a | 405 / 15.94 | 555 / 21.85 | 705 / 27.75 | 855 / 33.66 | 1005 / 39.57 | 1210 / 47.64 | |||

| b | 177 / 6.97 | 206 / 8.11 | 235 / 9.25 | 265 / 10.43 | 294 / 11.57 | 330 / 12.99 | |||

| c | 496 / 19.53 | 650 / 25.59 | 802 / 31.57 | 987 / 38.86 | 1137 / 44.76 | 1336 / 52.60 | |||

| d | 900 / 35.43 | 1200 / 47.24 | 1500 / 59.06 | 1820 / 71.65 | 2120 / 83.46 | 2525 / 99.41 | |||

| f | 450 / 17.72 | 600 / 23.62 | 750 / 29.53 | 920 / 36.22 | 1070 / 42.13 | 1270 / 50.00 | |||

| g | 51 / 2.01 | 80 / 3.15 | 109 / 4.29 | 138 / 5.43 | 167 / 6.57 | 204 / 8.03 | |||

| EB-IIA with cone / nozzle** | |||||||||

| DN | 200 / 8" | 300 / 12" | 400 / 16" | 500 / 20" | 600 / 24" | 800 / 32" | |||

| DN2 | ≤200 / 8“ | ≤300 / 12“ | ≤400 / 16“ | ≤500 / 20“ | ≤600 / 24“ | ≤800 / 32“ | |||

| b* | 401 / 15.94 | 456 / 17.95 | 535 / 21.06 | 614 / 24.17 | 693 / 27.28 | 830 / 32.68 |

Combination (DN/DN2) for EB with cone

Flow capacity charts for EB-DN/DN2-IIA/IIB with cone upon request

| DN | 50 / 2“ | 80 / 3“ | 100 / 4“ | 150 / 6“ | 200 / 8“ | 300 / 12“ | 400 / 16“ | 500 / 20“ | 600 / 24“ | 800 / 32“ |

| DN2 | ||||||||||

| 20 / ¾“ | IIA / IIB | IIA / IIB | IIA / IIB | IIA / IIB | ||||||

| 25 / 1“ | IIA / IIB | IIA / IIB | IIA / IIB | IIA / IIB | ||||||

| 32 / 1¼" | IIA / IIB | IIA / IIB | IIA / IIB | IIA / IIB | ||||||

| 40 / 1½" | IIA / IIB | IIA / IIB | IIA / IIB | IIA / IIB | ||||||

| 50 / 2“ | IIA / IIB | IIA / IIB | IIA / IIB | IIA / IIB | IIA | |||||

| 65 / 2½“ | IIA / IIB | IIA / IIB | IIA / IIB | |||||||

| 80 / 3“ | IIA / IIB | IIA / IIB | IIA / IIB | IIA | IIA | |||||

| 100 / 4“ | IIA / IIB | IIA / IIB | IIA | IIA | ||||||

| 125 / 5“ | IIA / IIB | IIA | ||||||||

| 150 / 6“ | IIA / IIB | IIA | IIA | IIA | ||||||

| 200 / 8“ | IIA | IIA | IIA | IIA | IIA | |||||

| 250 / 10“ | IIA | IIA | IIA | |||||||

| 300 / 12“ | IIA | IIA | IIA | |||||||

| 350 / 14“ | IIA | IIA | ||||||||

| 400 / 16“ | IIA | IIA | IIA | |||||||

| 450 / 18“ | IIA | IIA | IIA | |||||||

| 500 / 20“ | IIA | IIA | ||||||||

| 600 / 24“ | IIA | |||||||||

| 700 / 28“ | IIA |

Material selection for housing

| Design | A | B |

| flange ring | Steel | Stainless Steel |

| Weather hood | Steel | Stainless Steel |

| cone / nozzle | Steel | Stainless Steel |

| Flame arrester unit | A, B, C | B, C |

Material combinations of flame arrester unit

| Design | A | B | C |

| FLAMEFILTER® cage | Steel | Stainless Steel | Stainless Steel / Hastelloy |

| FLAMEFILTER® | Stainless Steel | Stainless Steel | Hatselloy |

| Spider ring | Steel | Stainless Steel | Stainless Steel / Hastelloy |

Selection of explosion group

| MESG | Expl. Gr. (IEC / CEN) | Gas Group (NEC) |

| > 0,90 mm | IIA | D |

| ≥ 0,50 mm | IIB | B |

Flange connection type

| EN 1092-1 (without cone); EN 1092-1; Form B1 (with cone / nozzle) |

| ASME B16.5 (without cone); ASME B16.5 CL 150 R.F. (with cone / nozzle) |

Design Types and Specifications

There are three different designs:

Deflagration flame arrester, end-of-line, basic design | EB |

End-of-line deflagration flame arrester, with cone | EB - DN/DN2 |

End-of-line deflagration flame arrester, with cone and heating jacket | EB - H - DN/DN2 |

Special designs available on request

Flow Capacity Chart

Remark: Flow capacity charts for EB-DN/DN2-IIA/IIB with cone upon request

The flow capacity charts have been determined with a calibrated and TÜV certified flow capacity test rig. Volume flow V in (m³/h) and CFH refer to the standard reference conditions of air ISO 6358 (20°C, 1bar). For conversion to other densities and temperatures refer to Sec. 1: “Technical Fundamentals”.