LH/AD-T

Deflagration Flame Arrester, short time burning-proof, End-of-Line

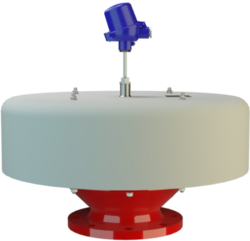

- weather hood with protection screen protects the PROTEGO® flame arrester unit against environmental impact, such as nesting animals and weather conditions

- available for DN 50/2“- bis DN 800/32“- pipes

- trouble-free maintenance

- advanced design for higher operating temperatures

- provides protection against atmospheric deflagrations and short-time burning

- low operating and lifecycle costs

- cost-effective flame arrester

- cost-effective spare parts

Función y Descripción

The PROTEGO® LH/AD-T end-of-line deflagration flame arrester provides protection against flame transmission through atmospheric deflagration and short time burning on the flame arrester element. The device is typically installed on vent lines of vessels and plant equipment which are not pressurized. The device is equipped with a temperature sensor which immediately detects a flame on the FLAMEFILTER® surface. After the flame is detected, a secondary measure, such as inerting or closing of a shut-off valve to block the vapor flow to the device, should activate within 60 seconds and extinguish the flame so that the system can operate safely. The device prevents flame transmission from short time burning and atmospheric deflagration into the vessel or plant.

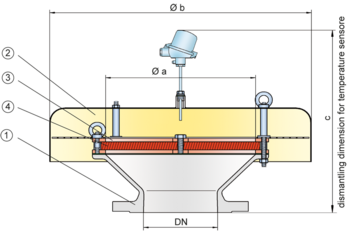

The PROTEGO® LH/AD-T consists of the housing (1), a weather hood (2), and the PROTEGO® flame arrester unit (3). The device is equipped with a metal weather hood. The FLAMEFILTER® (4) gap size depends on the device’s intended use. Specifying the operating conditions, such as the temperature, explosion group, and the composition of the fluid, enables PROTEGO® to select the best end-of-line deflagration flame arrester for your application. The PROTEGO® LH/AD-T series end-of-line deflagration flame arrester is available for substances from explosion groups IIA to IIC (NEC groups D to B).

The standard design can be used with an operating temperature of up to +60°C / 140°F. Devices with special approval for higher temperatures are available upon request.

EU conformity according to the currently valid ATEX directive. Approvals according to other national/international regulations on request.

Dimensiones

To select the nominal size (DN), please use the flow capacity charts on the following pages

| DN | a | b | c* | c* |

| IIB3 | IIC | |||

| 50 / 2" | 100 / 3.94 | 240 / 9.45 | 530 / 20.87 | 550 / 21.65 |

| 80 / 3" | 150 / 5.91 | 295 / 11.61 | 560 / 22.05 | 580 / 22.83 |

| 100 / 4" | 200 / 7.87 | 350 / 13.78 | 585 / 23.03 | 605 / 23.82 |

| 150 / 6" | 300 / 11.81 | 600 / 23.62 | 630 / 24.80 | 655 / 25.79 |

| 200 / 8" | 300 / 11.81 | 600 / 23.62 | 630 / 24.80 | 655 / 25.79 |

| 250 / 10" | 400 / 15.75 | 800 / 31.50 | 750 / 29.53 | 770 / 30.31 |

| 300 / 12" | 400 / 15.75 | 800 / 31.50 | 740 / 29.13 | 760 / 29.92 |

| 350 / 14" | 600 / 23.62 | 1000 / 39.37 | 800 / 31.50 | 820 / 32.28 |

| 400 / 16" | 600 / 23.62 | 1000 / 39.37 | 790 / 31.10 | 815 / 32.09 |

| 500 / 20" | 700 / 27.56 | 1200 / 47.24 | 810 / 31.89 | 835 / 32.87 |

| 600 / 24" | 800 / 31.50 | 1200 / 47.24 | 935 / 36.81 | 960 / 37.80 |

| 700 / 28" | 1000 / 39.37 | 1500 / 59.06 | 975 / 38.39 | 995 / 39.17 |

| 800 / 32" | 1200 / 47.24 | 1700 / 66.93 | 1015 / 39.96 | 1035 / 40.75 |

Selección de materiales para la vivienda

| Design | A | B |

| Housing | Steel | Stainless Steel |

| Weather Hood | Stainless Steel | Stainless Steel |

| Protection screen | Stainless Steel | Stainless Steel |

| Flame arrester unit | A, B | B |

Combinación de materiales para la unidad apagallamas

| Design | A | B |

| FLAMEFILTER® cage | Steel | Stainless Steel |

| FLAMEFILTER® | Stainless Steel | Stainless Steel |

Selección del grupo de explosión

| MESG | Expl. Gr. (IEC / CEN) | Gas Group (NEC) |

| ≥ 0,65 mm | IIB3 | C |

| < 0,5 mm | IIC | B |

Especificación de la máx. temperatura de operación

| ≤ 60°C / 140°F | Tmaximum allowable operating temperature in °C |

| - | Designation |

Tipo de bridas de conexión

| EN 1092-1; Form B1 |

| ASME B16.5 CL 150 R.F. |

Modelo y especificación

Following designs are available:

Deflagration flame arrester, end-of-line, basic design | LH/AD-T |

Special designs available on request

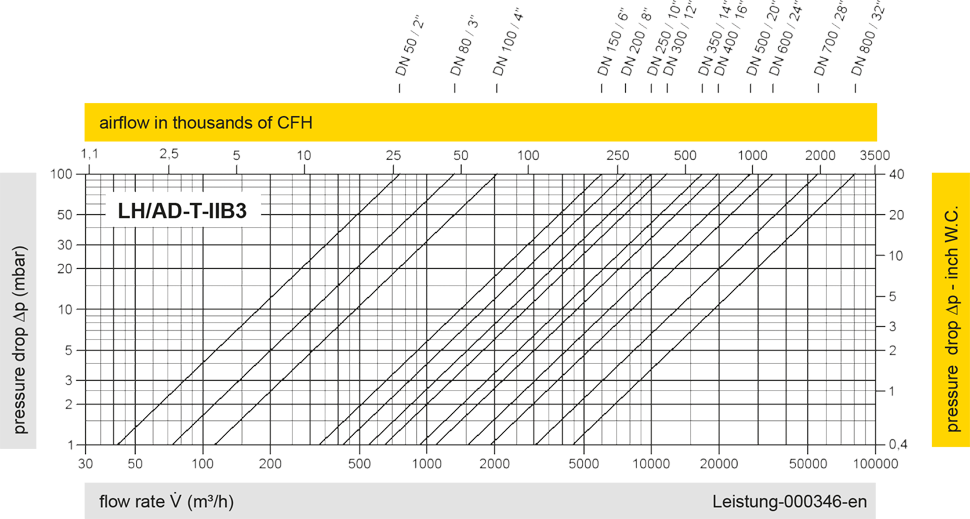

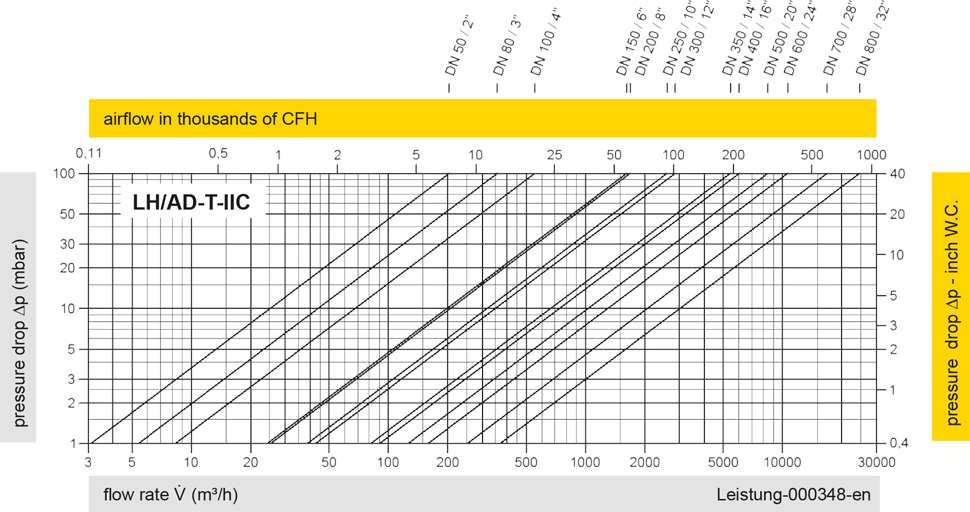

Diagrama de flujo volumétrico

Los diagramas de flujo volumétrico han sido determinados con un banco de pruebas de caudal calibrado y certifi - cado por TÜV. El flujo volumétrico V. en [m³/h] y el CFH se refi eren a las condiciones estándar de referencia de aire según ISO 6358 (20°C, 1bar). La conversión a otras densidades y temperaturas están referidas en el Vol. 1: “Fundamentos Técnicos”.