BE/HK-E

Deflagration Flame Arrester, endurance burning proof, End-of-Line

- endurance burning protection for alcohols and hydrocarbons with MESG ≥ 0,85mm

- weather hood protects the PROTEGO® flame arrester unit against environmental impact, such as nesting animals and weather conditions

- in case of fire, the weather hood opens, allowing the flame to be seen from a far distance

- centrally aligned melting element is resistant to chemicals

- modular design enables replacement of individual FLAMEFILTER® discs

- trouble-free maintenance

- provides protection against atmospheric deflagrations and endurance burning

- cost-effective spare parts

Función y Descripción

The PROTEGO® BE/HK-E end-of-line deflagration flame arrester was specifically developed for vessels which are not pressurized and store ethanol or other alcohols. The combustion of alcohol requires a modified flame arrester element design to provide protection against endurance burning. In addition, the device provides protection against atmospheric deflagration. It is typically installed on in-breathing and out-breathing vent lines to prevent flame transmission into the vessel or plant caused by endurance burning or atmospheric deflagration.

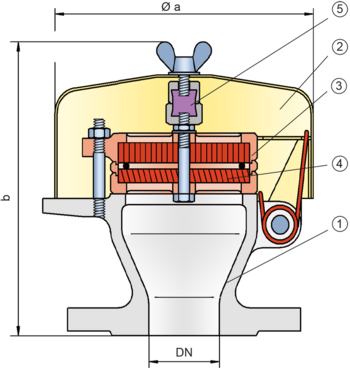

The PROTEGO® BE/HK-E consists of the housing (1), a weather hood (2), and the PROTEGO® flame arrester unit (3). During normal operation, the metal weather hood is in a closed position. If a stabilized flame burns on the flame arrester element surface, the melting element (5), located in a center position, will melt, and the spring-loaded weather hood will open. The PROTEGO® flame arrester unit consists of two FLAMEFILTER® discs (4) which are installed in a FLAMEFILTER® casing. The PROTEGO® BE/HK-E end-of-line deflagration flame arrester is available for alcohols and other substances with MESG ≥ 0,85mm.

The standard design can be used for operating temperatures up to +60°C / 140°F.

Type-approved in accordance with the current ATEX Directive and EN ISO 16852, as well as other international standards.

Dimensiones

To select the nominal size (DN), please use the flow capacity charts on the following pages

| DN | 20 / ¾" | 25 / 1" | 32 / 1¼" | 40 / 1½" | 50 / 2" | 65 / 2½" | 80 / 3" |

| a | 163 / 6.42 | 163 / 6.42 | 163 / 6.42 | 183 / 7.20 | 183 / 7.20 | 218 / 8.58 | 218 / 8.58 |

| b | 180 / 7.09 | 177 / 6.97 | 177 / 6.97 | 190 / 7.48 | 190 / 7.48 | 200 / 7.87 | 200 / 7.87 |

Selección de materiales para la vivienda

| Design | B | C |

| Housing | Steel | Stainless Steel |

| Weather Hood | Steel | Stainless Steel |

| Flame arrester unit | A | A, B |

Combinación de materiales para la unidad apagallamas

| Design | A | B |

| FLAMEFILTER® cage | Stainless Steel | Stainless Steel |

| FLAMEFILTER® | Stainless Steel | Hastelloy |

| Spacer | Stainless Steel | Hastelloy |

Selección del grupo de explosión

| MESG | Expl. Gr. (IEC / CEN) | Gas Group (NEC) |

| ≥ 0,85 mm | IIB1 | – |

Tipo de bridas de conexión

| EN 1092-1; Form B1 |

| ASME B16.5 CL 150 R.F. |

Modelo y especificación

There are two different designs:

End-of-line deflagration flame arrester, basic design | BE/HK-E - – |

End-of-line deflagration flame arrester with heating jacket | BE/HK-E - H |

Special designs available on request

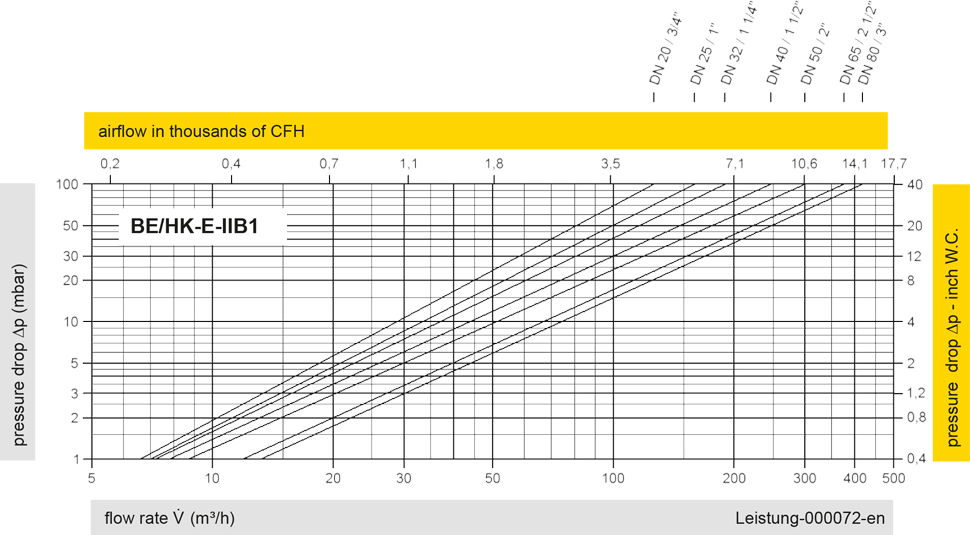

Diagrama de flujo volumétrico

Los diagramas de flujo volumétrico han sido determinados con un banco de pruebas de caudal calibrado y certifi - cado por TÜV. El flujo volumétrico V. en [m³/h] y el CFH se refi eren a las condiciones estándar de referencia de aire según ISO 6358 (20°C, 1bar). La conversión a otras densidades y temperaturas están referidas en el Vol. 1: “Fundamentos Técnicos”.