Innovations

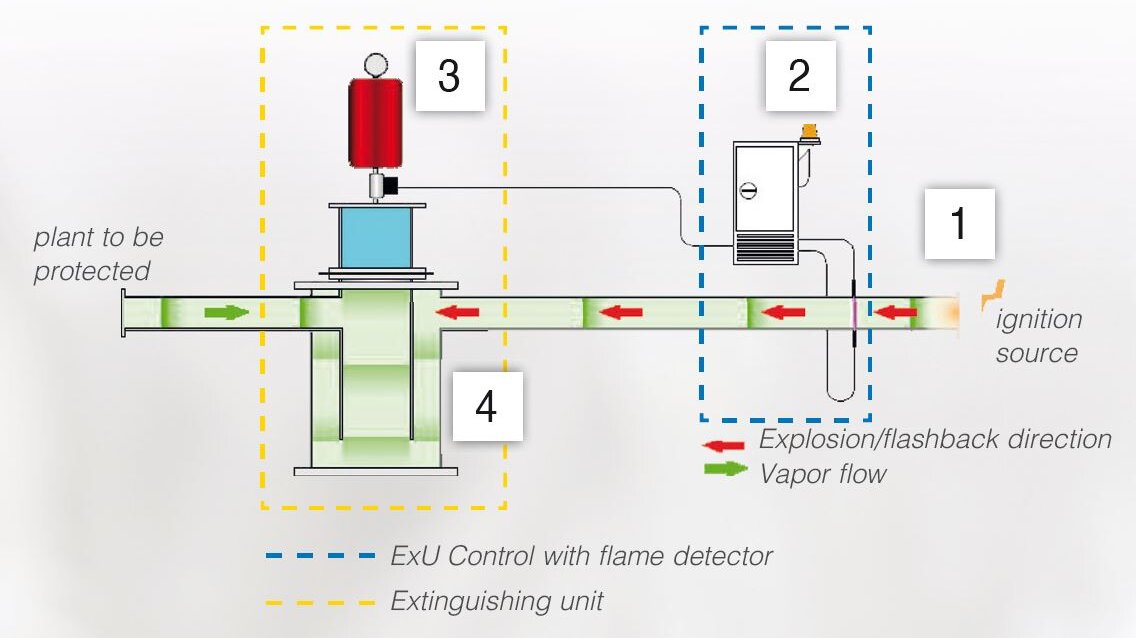

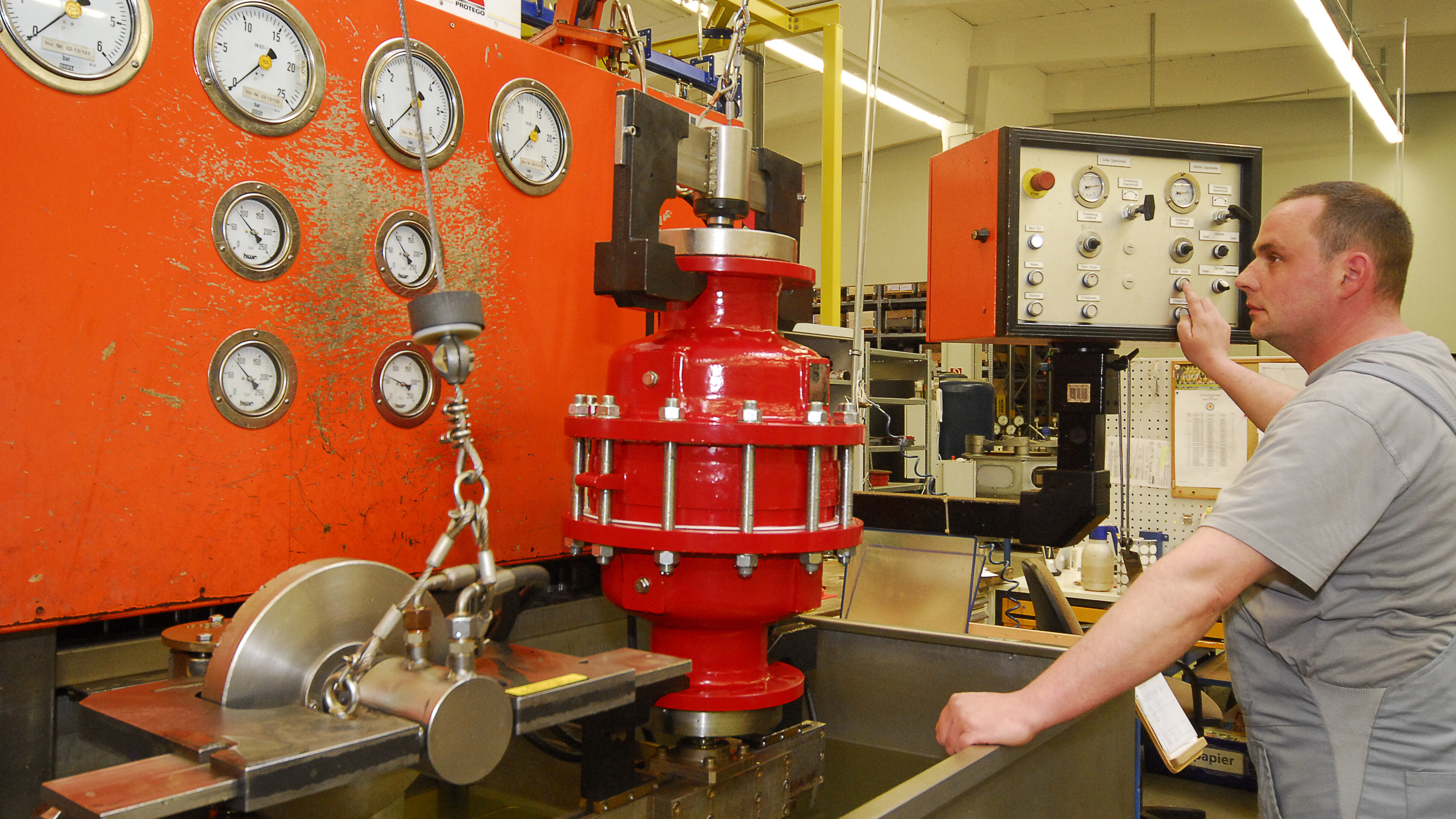

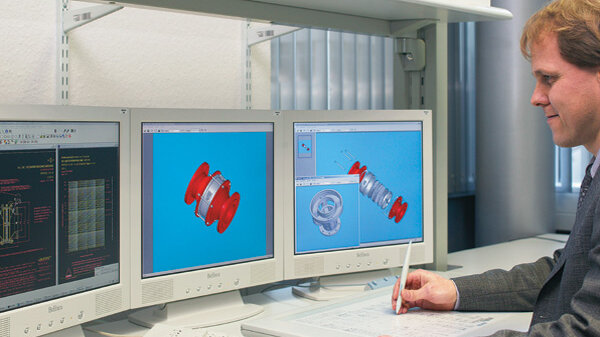

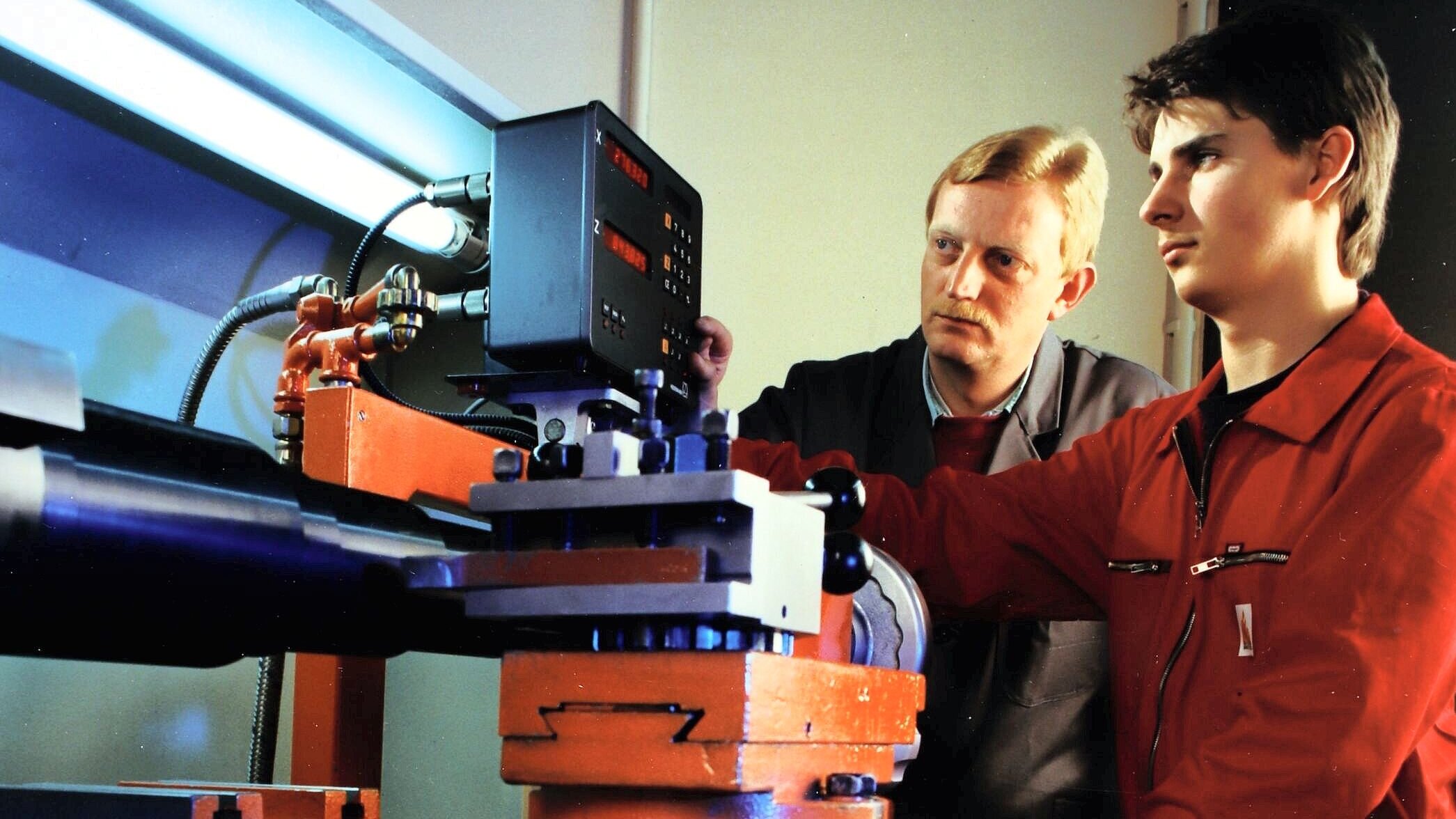

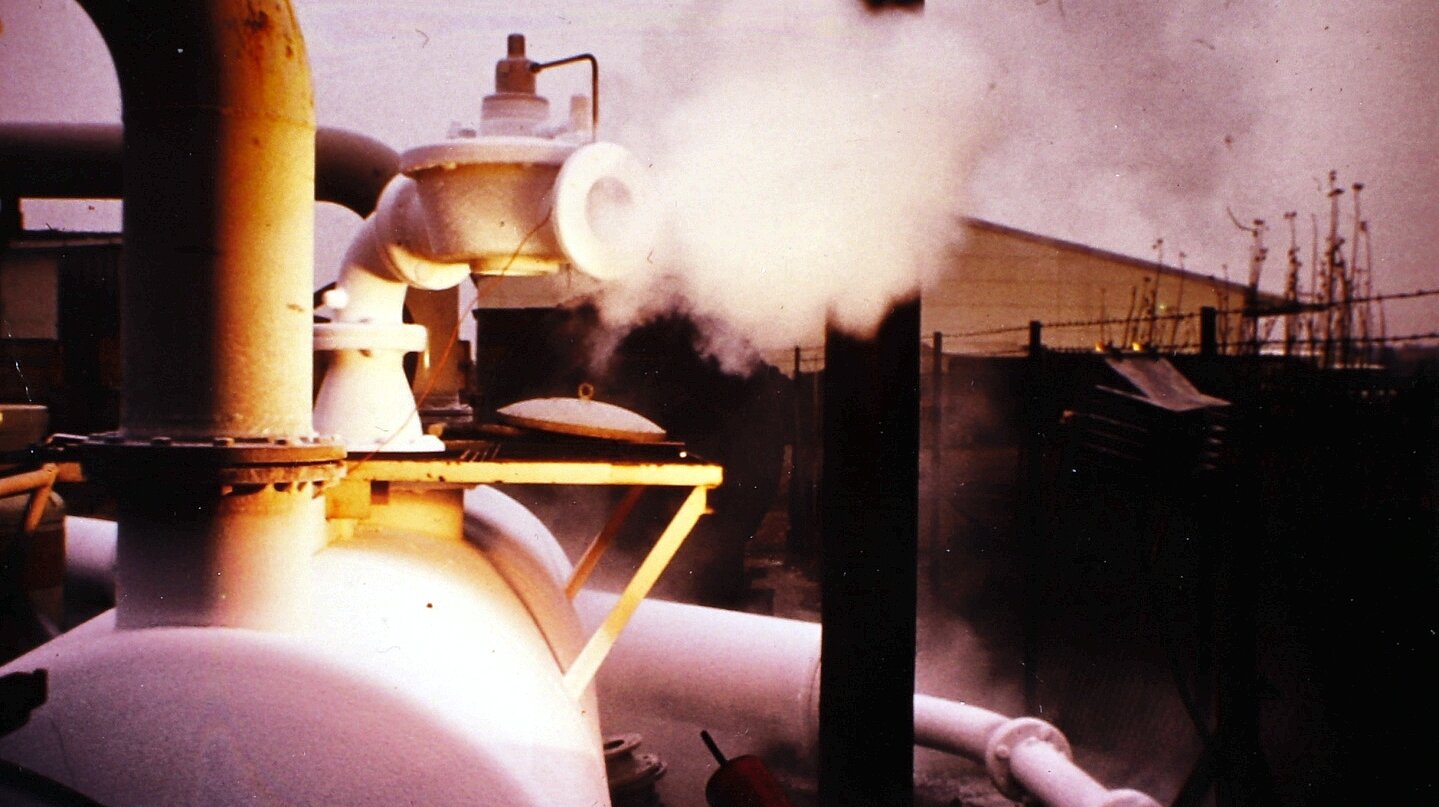

PROTEGO® devices are designed with process safety as the primary objective. Our standard and custom-made solutions comply with current national and international guidelines.

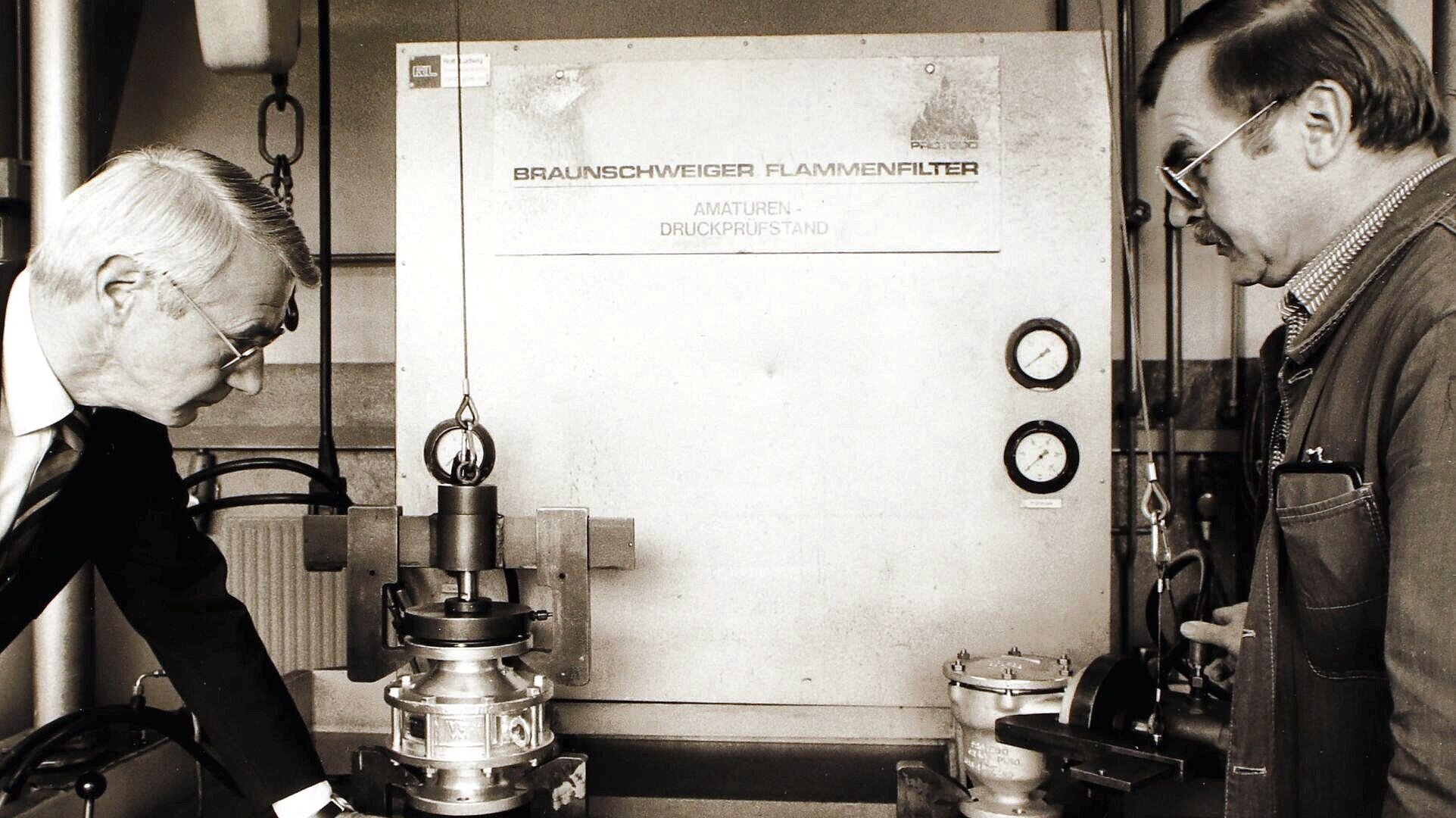

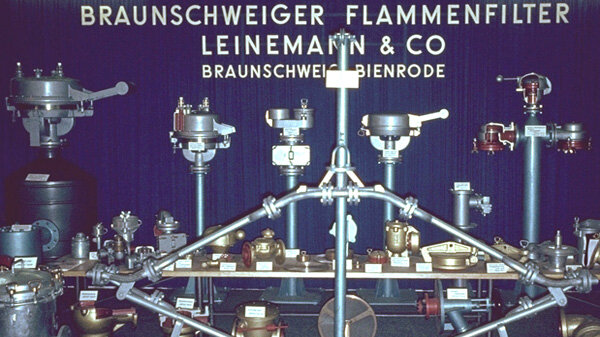

A Family Business with a tradition for innovation, becomes the global market leader.

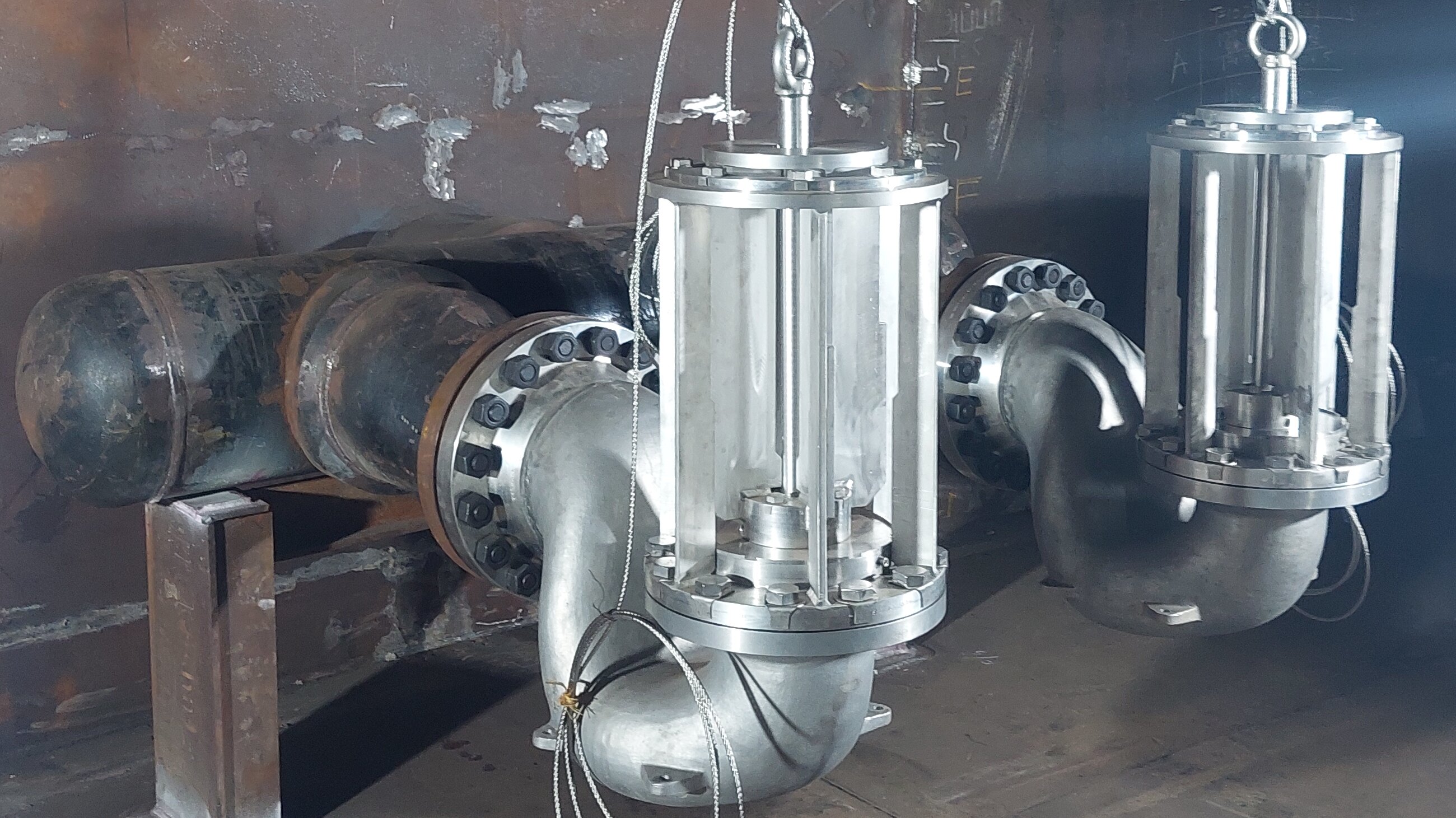

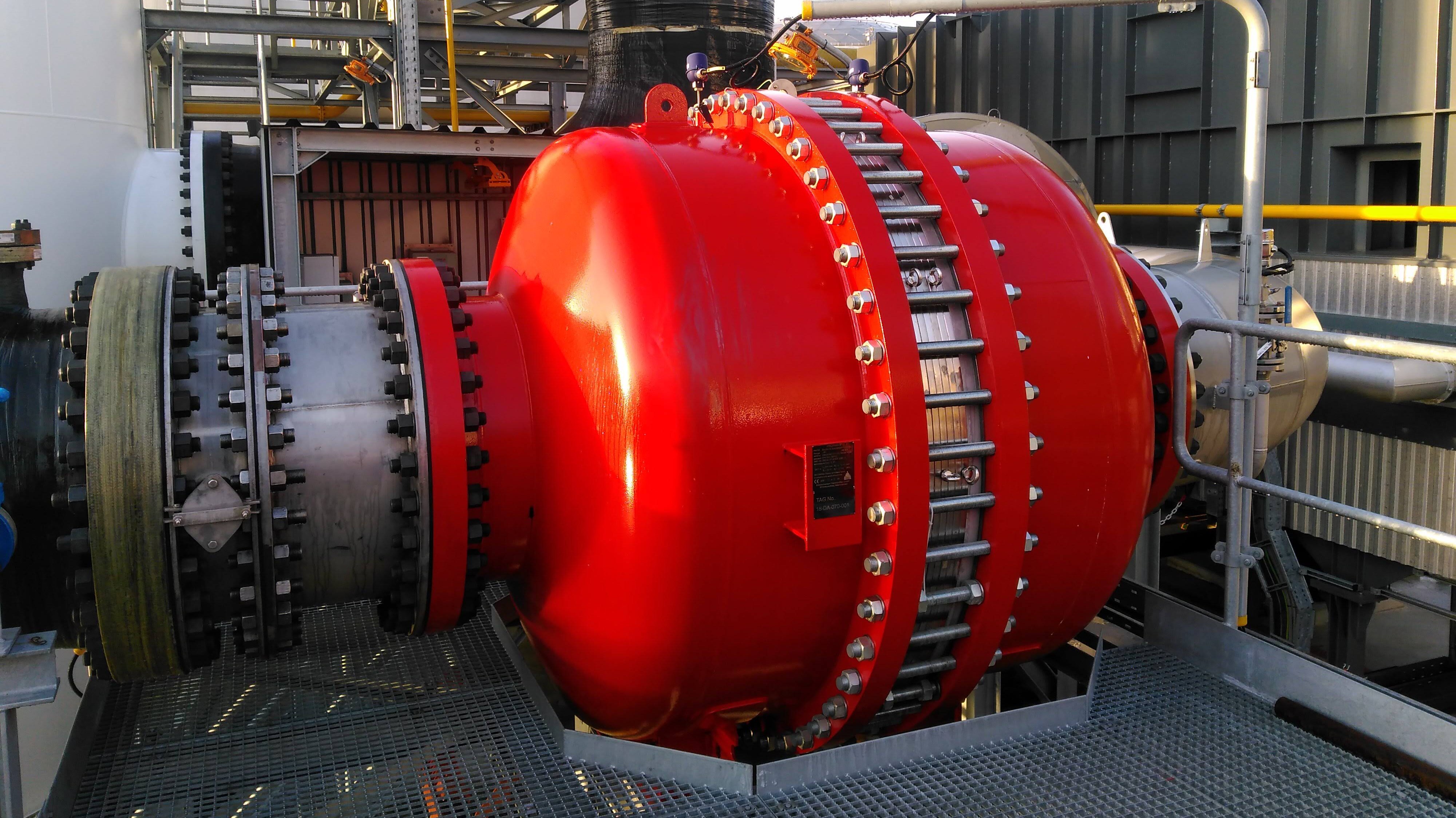

2016 - World’s first in-line liquid detonation flame arrester for higher temperatures